INTRODUCTION

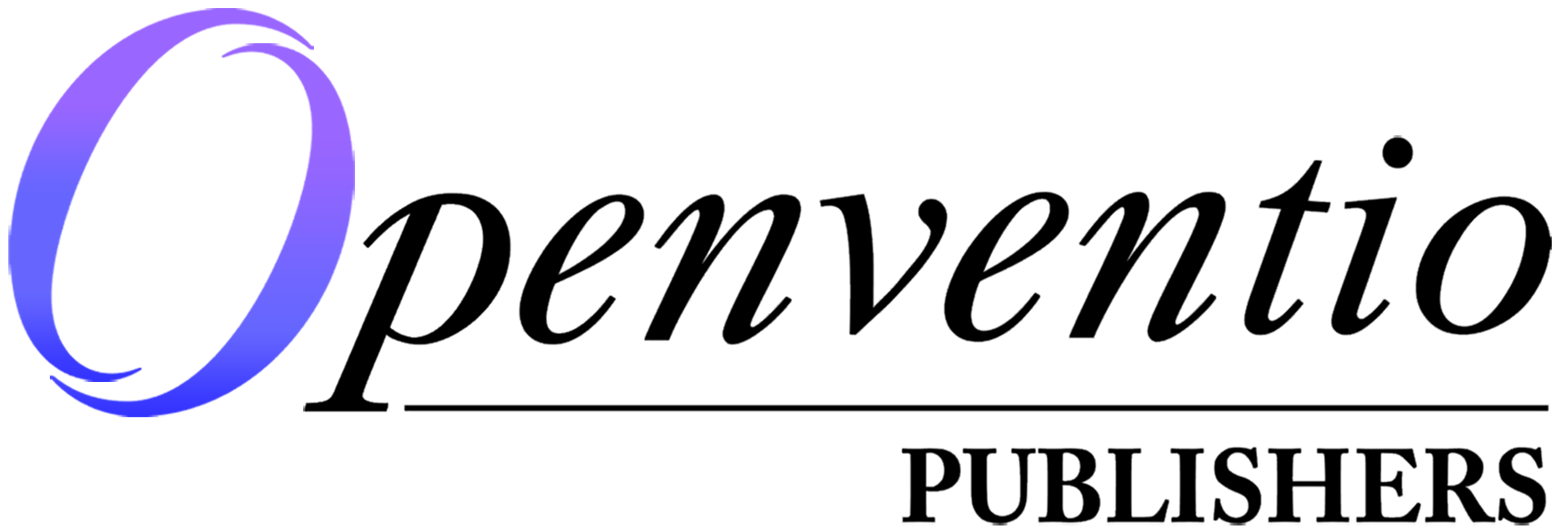

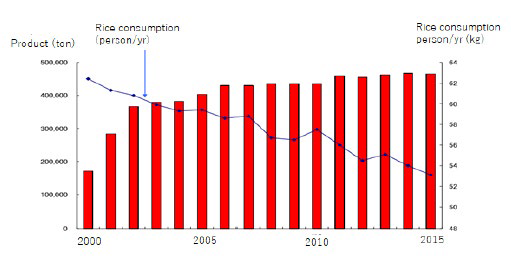

The taste and palatability of rice are inversely proportional to its nutritional value (Figure 1). The taste of rice depends on natural conditions, for example: the rice species, harvesting methods, or the climate. However, the method of rice processing after harvest is also very important.1-3 In parallel with industrial development, consumers have sought “more delicious”, “easier to eat” and “more appealing” rice. Responding to such demands, the food industry has increasingly processed rice as a market commodity.4 Novel industrial methods have become popular, using a variety of milling machines, polishing machines, polishing whitening effects, and processing standards.2

Figure 1: Inverse Relationship Between the Nutritional Value and Taste of Rice.

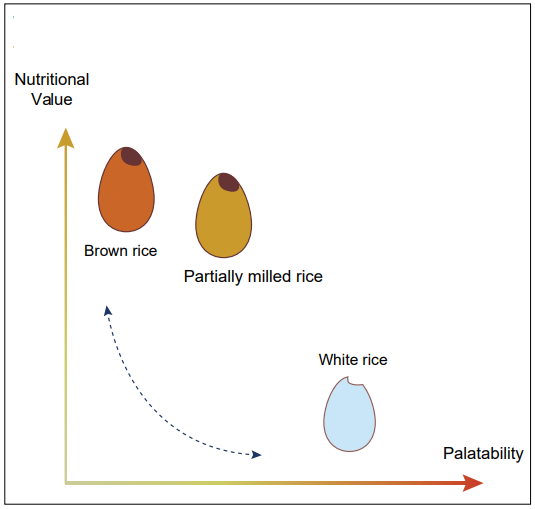

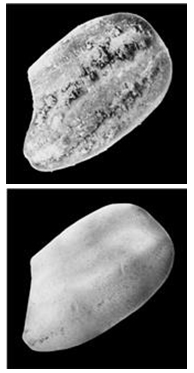

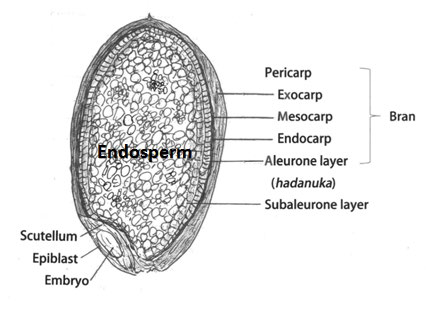

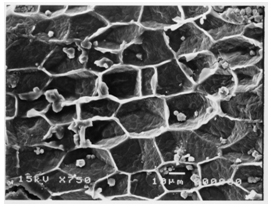

The health benefits of brown rice are well known, but consumers prefer polished white rice. Brown rice is made up of three concentric layers, respectively: (i) the outer layer of the endosperm (starch storage cell layer), (ii) the aleurone layer and (iii) the bran layer. Removing the bran layer makes the rice tastier (Figure 2).

Figure 2: Three External Layers of Brown Rice. These Cover Endosperm with Starch.

Proteins, vitamins, and other functional nutrients are mostly present in the bran layer. They are covered by an extremely hard waxy layer, which decreases the palatability of full grains.

Historically, several methods have been employed to remove bran: (i) the washing method (rinse off the skin bran with water and then dry), (ii) the grind method (rub the rice with a brush, nonwoven fabric, or polishing machine, to remove the skin bran), (iii) the neo-tasty method (add a small amount of water to rice, pressurize it, stir it, remove skin bran with hot granulated tapioca, and let it dry).

Until the 1950s’ white rice was sold with a large amount of white bran powder covering the surface of each grain. Since 1955, rice mill manufacturers have been increasing the commodity value of rice. They developed the so-called “frictiontype jet rice mill”, where by the bran powder adhering to the white rice surface is removed by air-flow to produce a glistening appearance.4,5This results in the removal of the outer layer of the endosperm. This type of rice mill has continuously been used as the mainstream technique for rice processing from around 1965 until now

Around 1975, the method was improved to further increase the commodity value of rice by using a friction-type jet rice mill to let the rice grains rub against each other, leaving a tiny amount of water attached to the white rice surface. This method scraped the exterior of the softened outer layer of the endosperm and smoothed it to make the rice grain surface glossy.6

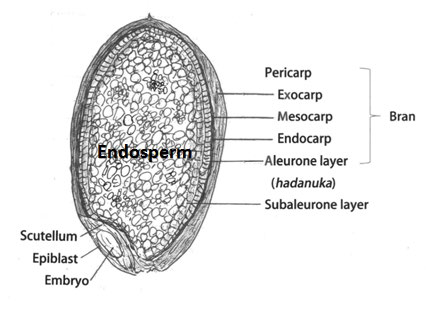

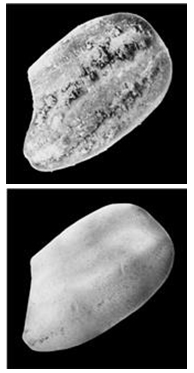

Since rice grains now appear extremely smooth and shine like a pearl, the commodity value increased a lot compared with former rice (Figure 3).

As small amount of water is added at the time of polishing, the method produced is charge water should bediluted to fit the environmental protection law. Indeed, rice washing waters contain large amounts of phosphate and nitrogen, causing water pollution in rivers and lakes by overgrowth of microorganisms and algae.7,8

Rice mills processing paddy rice release huge amounts of wastewaters and other by-products, including toxic inorganic and organic contaminants which cause environmental pollution. Accordingly, cost-effective techniques for removing contaminants are needed.

The “bran grind method” (BG method) was invented by Keiji Saika as an alternative method of rice processing avoiding the use of water.9,10 To make rinse-free rice, the viscosity of bran itself is used to remove “skin bran,” which is normally the basic component of turbid rice-washing water. Preserving the endosperm surface is also important to keep the taste.

METHOD

The Development of BG-Type, Rinse-Free Rice Machine

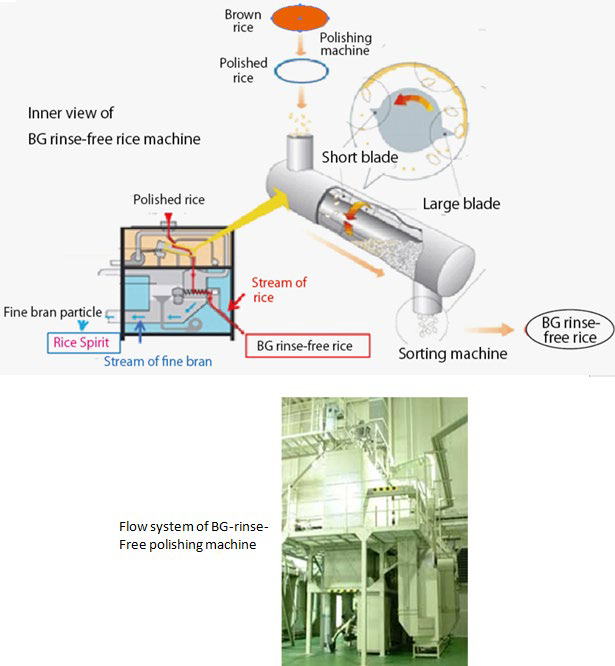

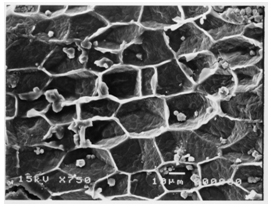

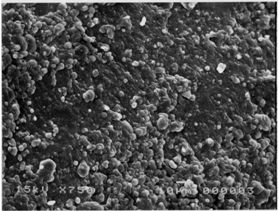

The purpose of our research was to develop a method and device for manufacturing rinse-free rice that does not require wastewater treatment and can consistently produce high-quality rice. The adhesive properties of fine bran (hadanuka) on the surface of polished rice was exploited to aggregate each other from the surface of rice (Figure 3).

Figure 3: Surface of Polished Rice. Tiny Bran Particles Cover the Surface of Polished Rice. Scanning Electron Microscopic View (x750).

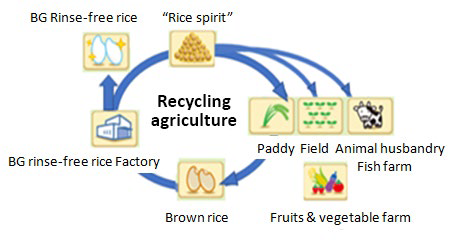

A new machine was invented and improved to adjust the best conditions to separate remnant bran from rinse-free rice. Sorted bran was further processed into secondary bran products, such as fertilizer, animal feed or baits for fisheries.

Nutrients

The nutrient contents of BG rinse-free rice, original polished white rice, and hand washed white rice were measured at the Nippon Food Analysis Center, Tokyo, Japan.11 Energy, major nutrients, vitamins, minerals and number of bacilli and heatresistant spores were measured according to guidelines of the Ministry of Agriculture, Forest and Fishery.

Taste

The taste of the rinse-free rice made by the BG method or other washing method was compared to that of ordinary polished white rice. The Taste Visualization scale (Aissy Laboratory, Tokyo, Japan) was used.12 The Taste analysis machine and software computes taste by using statistical inferences from six different taste parameters: sweet, salty, acidic, bitter, umami and koku. Koku means a kind of deepness in the taste. Each rice sample was tested 10-14 days after processing rice from brown rice.

Figure 4: Polished Rice Made by Water Washing Method (Upper) and BG Method (Lower).

RESULTS

Development of the BG Machine

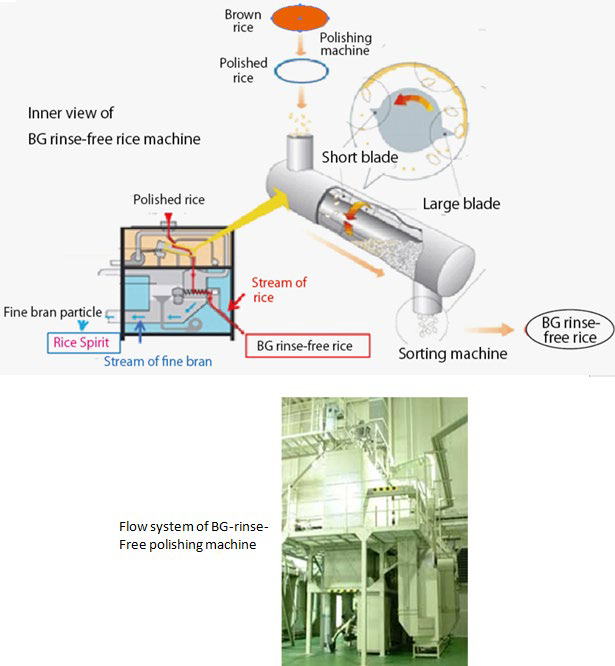

Separation of hadanuka from the surface pits of polished rice is done through the following method (Figure 5), typically with an output of about 50 kg/minute. White rice is introduced into the orifice of a cylinder and pushed forward by a spiral blade.

Figure 5: Appearance of BG Rinse-Free Rice Making System. Schema of the Machine (Upper) and Whole Integrated System (Lower)

The inside of the stainless steel cylinder, a thick rotating shaft has 3-5 short blades and large blades alternatively. The short blades stir rice grain to remove remnant fine bran of the rice surface, which adheres on the inner surface of the cylinder. The large blades scratch off the stuck bran on the wall. The mixture of rice and detached tiny bran particles move to the sorting part of the machine, and clear rinse-free rice is obtained (Figure 5a).

In summary, four steps were carried out: (1) Flip fine bran by the short blade toward inner wall of the cylinder. (2) Attached wall bran grows larger by adhesion with other fine bran. (3) The large blade scratched off the wall attached bran layer. (4) Mixture of rinse-free rice and tiny particles of fine bran are sorted.

The removal of hadanuka from the surface of rice is shown by scanning electron microscopy (Figure 6).

Figure 6: Surface of BG Rinse-Free Rice. Fine Bran has been Removed from the Surface. Scanning Microscopic view (x750)

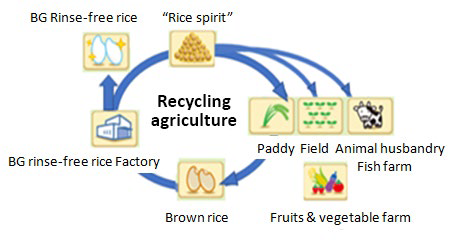

Then, bran and rice are separated by the sorting machine. Bran contains lipase and other enzymes, which are inactivated by heating after adding a small amount of water to make larger ball, about 1 cm in diameter. It is named “kome-no-sei” which means bran spirit. This is used as fertilizer and bait for farming fishes in the paddy (Figure 7). This system meets the objectives of the recycling agriculture.

Figure 7: Recycling Agriculture Supported the BG Rinse-Free Rice Factory.

The entire process does not require water treatment at all. The energy expenditure to make 1 kg rinse-free rice is estimated to be 18.5 g CO2.

Nutrientsin Rinse-Free Rice

Nutrients in the rinse-free rice are similar to hand-washed rice (Table 1). Major nutrients, such as carbohydrate, protein and fat are not significantly different from the original rice. Concentrations of vitamin B1, B6, vitamin E, niacinare less than in the original rice, but higher than in hand-washed rice. The concentration of phosphate and potassium is as low as in hand-washed rice.

The number of bacilli is the lowest in rinse-free rice, reflecting a hygienic operation.

In addition, the fatty acid score of rinse-free rice is 5.8 mg/100 g after one month of processing, compared to 11.7 mg/100 g with polished ordinary rice.

Table 1: Comparison of Nutrients Among Ordinary Polished Rice, Hand-Wash and Dried Rice, and BG Rinse-Free Rice.

*number of heat tolerable spore by soaking in boiling water for 10 min

| Table 1: Comparison of Nutrients Among Ordinary Polished Rice, Hand-Wash and Dried Rice, and BG Rinse-Free Rice. |

|

Unit

|

Ordinary rice |

Hand wash & dry |

BG rinse free rice

|

| Water |

g/100 g

|

13.8 |

16.1 |

14.1

|

| Protein |

g/100 g

|

5.3 |

4.9 |

5.1

|

| Fat |

g/100 g

|

1.2 |

1.0 |

1.0

|

| Ash |

g/100 g

|

0.4 |

0.2 |

0.2

|

| Carbohydrate |

g/100 g

|

79.3 |

77.8 |

79.6

|

| Energy |

kcal/100 g

|

364.0 |

355.0 |

363.0

|

| Phosphate |

mg/100 g

|

102.0 |

56.0 |

59.7

|

| Iron |

g/100 g

|

0.18 |

0.15 |

<0.1

|

| Calcium |

g/100 g

|

5.5 |

5.9 |

4.3

|

| Sodium |

g/100 g

|

0.4 |

0.9 |

0.4

|

| Potassium |

g/100 g

|

84.6 |

50.0 |

56.7

|

| Magnesium |

g/100 g

|

29.3 |

9.4 |

10.4

|

| Cupper |

ug/100 g

|

172.0 |

170.0 |

163.0

|

| Zinc |

mg/100 g

|

1.51 |

1.36 |

1.42

|

| vitamin B1 |

mg/100 g

|

0.1 |

0.03 |

0.05

|

| vitamin B2 |

mg/100 g

|

0.01 |

0.01 |

0.01

|

| vitamin B6 |

mg/100 g

|

0.11 |

0.025 |

0.035

|

| vitamin E |

mg/100 g

|

0.2 |

<0.1 |

0.1

|

| Niacin |

mg/100 g

|

1.06 |

0.24 |

0.44

|

| Baccilus |

n/100 g

|

3.3×103 |

7.5×104 |

1.2×103

|

| Spore* |

n/100 g

|

<300 |

<300 |

<300

|

Taste of Rinse-Free Rice

BG rinse-free rice ranked the best in comprehensive evaluations of taste (sweetness+umami-bitterness). The higher the point of sweetness and umami, the more taste increased a difference of 0.2 in each factor was easily recognizable by human sensory organ.

Credibility of BG Machine

The core technology is protected by a patent (#P2615314). Land facilities for industrial production were identified by a contractor in various places. The core part of the mill is not visible from the outside. The raw material is introduced through a belt conveyor for rinse-free processing. Because of confidential management, each mill is connected to the headquarters via a direct line, and facilities are operated by company engineers through an automatic control system.

DISCUSSION

Comparison with other Rinse-Free Rice Producing Machine

Around 1993, a new rinse-free rice machine called the BG type, was developed and marketed to prevent water pollution caused by turbid rice-washing water.9 White rice finished with a friction-type jet rice mill was further processed by the BG machine to turn the white rice into rinse-free rice that did not require washing (thus, no rice-washing water was discharged).

Around the time when the BG-type machine appeared on the market, another manufacturer had released a different type of rinsing machine. A simple prewashed-type rubbed hard on the white rice grains in water. It scraped the surface of endosperm, and could not successfully deal with large amounts of turbid rice-washed water generated in rice milling plants, so rice dealers became unable to use it consequently.

The tapioca-type, pre-wash rice machine washed white rice with a small amount of water and a large quantity of tapioca particles to wipe the rice-washed water on the surface of rice. The surface of white rice was grinded with added water to soften the bran layer and mechanically rubbed by tapioca particles heated to 100 °C for wiping off the viscous rice-washing water. As the surface layer of the endosperm is rich in nutrients and delicious, the removal of this part from the pre-washed rice led to poor eating quality.

Market share of BG type rinse-free rice

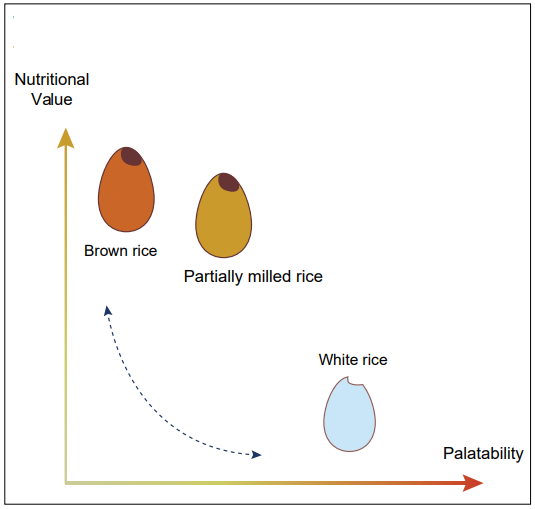

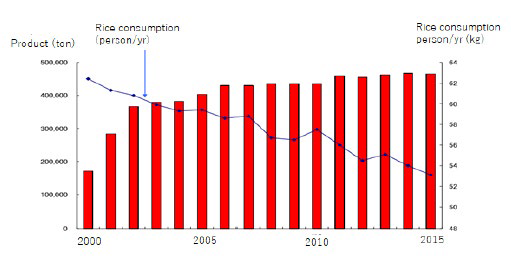

The consumption of rice by Japanese has steadily decreased from 74.6 kg/capita/year in 1985 to 56.9 kg/capita/year in 2013 (Figure 8). In 2014, the production of rinse-free rice was 467,000 tons, i.e., 6.5% of the total national rice consumption (7.22 million tons). However, the total annual rice consumption in Japanese market is estimated to be 4 to 5 million ton, so the rinse-free rice was considered to account for 10%.

Table 2: Taste of the BG Rinse-Free Rice, Non-BG Rice and Ordinary Rice.

| Table 2: Taste of the BG Rinse-Free Rice, Non-BG Rice and Ordinary Rice. |

|

Evaluation

|

Sweetness |

Salt |

Acid |

Bitter |

Umami |

Koku

|

| BG rinse-free rice |

3.71

|

2.68 |

1.24 |

1.15 |

1.14 |

2.24 |

4.00

|

| Non BG type rinse-free rice |

3.38

|

2.37 |

1.23 |

1.12 |

1.13 |

2.14 |

3.77

|

| Polished rice |

3.45

|

2.42 |

1.21 |

1.13 |

1.15 |

2.18 |

3.83

|

Figure 8: Rice Consumption in Japan.

Although, brand rice is popular as delicious, delicious rice cannot be obtained without good rice milling method and cooking method.13,14,15,17 These are all important together with the production method. The volume of waste water for washing polished rice is about ten times more of the weight of rice, and phosphate and nitrogen contained in the waste water cause environmental water pollution, so rinse-free rice is environmentally friendly. The BOD loading amount representing the index of water pollution is 10% or less of discharged water from ordinary milled rice.

Rinse-free rice is actively handled in many company’s cafeterias and major restaurants for business use. Recently, Japanese cuisine has been employed for most school lunches now, but for them, rice cooking is cumbersome. Among such circumstances rinse-free rice is employed by about half of school meals. There is a merit in terms of economic reason, such as saving time, unnecessary for washing machine and manpower. There is also an advantage to support rice-making farmers by supplying domestic rinse-free rice for school meals. About 30% of the major rice dealers in Japan have turned to rinse-free rice.

CONCLUSION

While human beings have first improved rice-processing technologies to enhance deliciousness, from now on we should equally aim at preserving the nutritional properties.18 However, enhancing deliciousness and preserving the nutritional properties are difficult to reconcile. Nevertheless, rice that meets both of these characteristics has been available as early as 2005. Novel techniques exist for converting waste products into energy and value-added products.

CONFLICTS OF INTEREST

The authors declare that they have no conflicts of interest.