INTRODUCTION

The guabiroba (Campomanesia xanthocarpa O. Berg) also known as “guavirova”, “guabiroba-miúda”, “guabirobeira-do-mato”, “gavira”, and “guabiroba-do-campo” is a fruit of the guabirobeira, a fruit-bearing tree from the Myrtaceae family belonging to one of the 3,600 species distributed in more than 100 genera of this bo- tanical family1,2,3,4,5 This fruit is native to the northeast, central west (Cerrado regions) and south of Brazil, however, it can also be found in South American countries such as Paraguay, Argentina, Bolivia and Uruguay.2,4,6,7,8,9 The name “guabiroba” refers to bitter fruit, in the Tupi-Guarani language spoken by specific indigenous groups in Brazilian regions.6

The fruits can be harvested at different stages of ripeness, which enhances fresh consumption or after processing as sweets, ice creams, fermented milks, homemade liqueurs, and jams.3,4,7,10 In addition, bioactive compounds from guabiroba fruits, leaves, and seeds have received attention in promising studies on the de- velopment of functional products, food packaging, and medicines due to their potential antioxidant, antithrombotic, antiproliferative, trypanocidal, and prebiotic activities.6,10,11,12,13,14,15

The consumption and processing of native fruits have received encouragement lately due not only to the technological potential but also to the diversification of fruit production for pro- cessing in a specific region and the high functional and nutritional significance for human health.16,17 For guabiroba, although it has a high potential for processing on an industrial scale, crop data are still scarce for the commercial use of the fruit.4,16 The knowledge and studies about this native Brazilian fruit, as well as its by-prod- ucts, contribute to adding value and enhancing the commercial and industrial application.18

This review aims to present the technological properties of guabiroba, bringing studies addressing the application of the fruit and by-products in the development of new products, the potential application of emerging technologies as well as expand- ing knowledge about this Brazilian fruit for an increase in its con- sumption and future industrial applications.

COMPOSITION AND PROPERTIES OF GUABIROBA

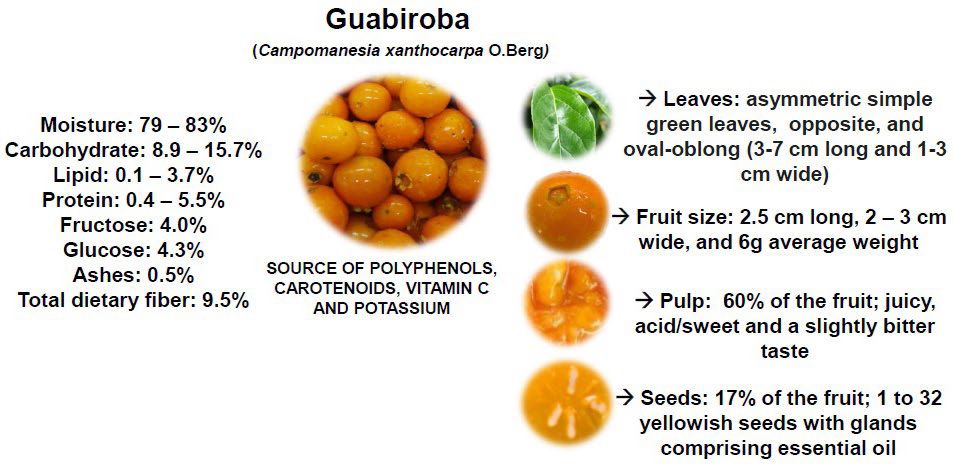

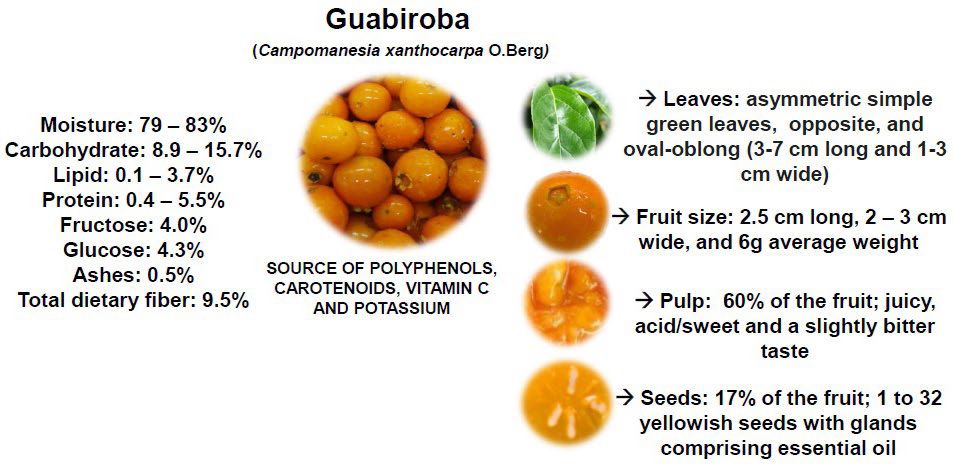

The Campomanesia xanthocarpa O. Berg species ( with botanical synonyms C. crenata, C. dusenii, C. littoralis, C. malifolia, and C. rhom- bea) is a shrub or tree-shaped, 10 to 20 meters high, 30 to 70 cm in diameter, with asymmetric simple green leaves, opposite, and oval-oblong (3-7 cm long and 1-3 cm wide).2,19 The fruits are clas- sified as small glabrous berries (2.5 cm long, 2-3 cm wide, and 6 g average weight), with a green epicarp when young and yellow- orange, thin and smooth when ripe.2,3,19 The endocarp is juicy, sweet, acid, with a slightly bitter taste, aromatic, and contains 1 to 32 yellowish seeds with glands comprising essential oil (Figure 1).3,7,19 In general, the fruit composition is 55% mesocarp, 18% epicarp, 13% seeds, 10% endocarp, and 3.9% chalice.6,7 It is a botanical species with good adaptability, being able to develop in dry, compact, and low fertility soils.19

Figure 1. Campomanesia Xanthocarpa O.Berg Properties

Concerning the nutritional composition, the guabiroba fruit is a good source of macronutrients, vitamins, and miner- als, with variable contents according to the climatic conditions, season, agronomic factors, soil conditions, management, variety, plant nutrition, and ripening stage (Table 1).2,6,16,17,20 The com- bination of these intrinsic and extrinsic factors influences the phytochemical metabolism of the plant, diversifying the content of bioactive compounds and vegetable composition17 However, even if growing conditions vary, the guabiroba fruits usually con- tain high moisture (79-84%), which characterizes the juiciness of the pulp, and low caloric value (57.3 kcal 100 g-1) due to the low concentration of carbohydrates, lipids, and proteins in the endo- carp, mesocarp and seeds.1,2,6,7

| Table 1. Nutritional, Physicochemical Composition and Antioxidant Properties of Campomanesia xanthocarpa O.Berg Fruits |

|

Parameter

|

Content (unit per 100 g) |

References

|

|

Moisture

|

79.0 – 83.0 gb |

2,3,6,7,17,20 |

| Carbohydrate |

8.9 – 15.7 ga |

2,20

|

|

Lipid

|

0.1 – 3.7 ga |

2,7,20 |

| Protein |

0.4 – 5.5 ga |

6,19,20

|

|

Total sugar

|

34.4 ga |

3,20 |

| Reducing Sugar |

8.3-34.1 ga |

3,7,20

|

|

Fructose

|

4.0 gb |

7 |

| Glucose |

4.3 gb |

7

|

|

Ashes

|

0.5 gb |

20 |

| Total dietary fiber |

6.3-9.7 ga |

2,20

|

|

Insoluble dietary fiber

|

9.5 ga |

20 |

| pH |

3.9-4.58b |

3,7

|

|

Total Titratable acidity

|

0.3-0.5 ga |

7,20 |

| Total soluble solids |

12.0-15.3b |

7,20

|

|

Vitamin A (Retinol)

|

0.2-0.9 µg REa |

2,20 |

| Vitamin C (Ascorbic Acid) |

17.8-233.0 mga |

2,7,20

|

|

Vitamin B1 (Thiamine)

|

3×10-3 µga |

17 |

| Vitamin B2 (Riboflavin) |

0.1-1.5 mga |

2,3,17, 20

|

|

Vitamin B5 (Pantothenic Acid)

|

0.3µga |

17 |

| Vitamin B6 (Pyridoxin) |

0.1 µga |

17

|

|

Vitamin B7 (Biotin)

|

0.3 µga |

17 |

| Essential oil |

0.2 gb |

2

|

|

Total Carotenoids

|

20.7-3.107 mgb |

16,17,20 |

| Total Polyphenols |

9033.2 mg CAEa |

20

|

|

Total Flavonoids

|

68.0 mg QEb |

3,16 |

| Total Anthocyanins |

3.2-11.7 mgb |

3

|

|

ABTS radical scavenging capacity

|

50.7 mmol TEa |

20 |

| K |

208.4 mgb |

2

|

|

Na

|

2.6 mgb |

2 |

| Ca |

28.4 mgb |

2

|

|

Mg

|

13.5 mgb |

2 |

| P |

14.9 mgb |

2

|

|

Zn

|

0.4 mgb |

2 |

| Fe |

0.6 mgb |

2

|

|

Cu

|

0.3 mgb |

2 |

| Mn |

0.12 mgb |

2

|

|

Se

|

0.12 mgb |

2 |

| Al |

0.32 mgb |

2

|

|

Ba

|

0.14 mgb |

2 |

| Pb |

0.13 mgb |

2

|

|

As

|

0.09 mgb |

2 |

| Ni |

0.12 mgb |

2

|

| Note: RE-Retinol equivalent; CAE-Chlorogenic acid equivalent; GAE-Gallic acid equivalent; QE-Quercetin equivalent; a Values expressed based on dry weight; b Values expressed based on fresh weight. |

In general, the guabiroba presents high nutritional prop- erties and can be considered a functional food, with higher car- bohydrate content when compared to protein and lipids (Table 1), which is characteristic in fruits belonging to the Myrtaceae fam- ily.7,16,21 The fruits contain high-levels of vitamin C (17.8-233.0 mg 100 g-1), which corresponds to up to six times the orange content, offering a potential benefit to human health due to the antioxidant activity, which acts on the mechanism of scavenging free radicals, related to aging processes and degenerative diseas- es.2,7,17 Guabiroba also presents considerable amounts of vitamin A (20-90 μg g-1 RE, Table 1), essential in the physiology of the retina, bone remodeling, epithelial tissue maintenance, and the reproductive system.2,6,22 It is estimated that the consumption of 10 fruits contributes approximately 5.4% fiber, 1.6% vitamin B2, and 8.5% vitamin C in the daily diet of adult individuals, when based on the recommended values by the World Health Organi- zation (WHO).2,23

Among the mineral’s composition, guabiroba is rich in potassium, calcium, sodium, phosphorus, iron, manganese and zinc (Table 1). Sodium and potassium contents influence the tex- ture of the fruit, with an increase in hardness by reducing the electrostatic repulsion of carboxyls present in the composition of plant cells.6,7 For iron contents, guabiroba presents higher lev- els (0.6 mg 100 g-1) than commonly consumed fruits, such as ba- nana (0.4 mg 100 g-1) and apple (0.1 mg 100 g-1).6,16

Phenolic compounds and carotenoids are non-nutritive compounds present in fruits and vegetables related to important benefits for health due to antioxidant, antimicrobial, anti-obesity, antihypertensive, antihyperglycemic activities, and neuroprotec- tive effects.24,25,26 The important antioxidant potential, in addition, may increase industrial interest in food formulations to replace preservatives, additives, and even artificial colorants, since carotenoids are fat-soluble pigments responsible for the orange, yellow, and red coloration.3,20,27 For Campomanesia xanthocarpa O. Berg composition, there is an interesting source of carotenoids (mainly β-carotene, lutein, cryptoxanthin, and zeaxanthin), with higher amounts of β- carotene (12.3-3400 mg 100 g-1, Table 2), considered the one with the greatest vitamin A potential, when compared to other fruits, such as papaya (0.04 mg 100 g-1), wa- termelon (0.36 mg 100 g-1), and orange (0.09 mg 100 g-1).3,17 The fruits also present high content of cryptoxanthin (9.31 mg 100 g-1), the main carotenoid that characterizes the orange-colored pulp in several fruits, standing out from other fruits such as nectarine (0.8 mg 100 g-1), papaya (0.5 mg 100 g-1) and apricot (0.6 mg 100 g-1).20

For total phenolic compounds, the guabiroba fruit presents higher amounts (9033.2 mg chlorogenic acid equivalent (CAE) 100 g-1, Table 1) when compared to conventional fruits, such as apples (150-350 mg GAE 100 g-1), grapes (720-1232 mg GAE 100 g-1), and some fruits also from Myrtaceae family such as yellow guava (Psidium cattleianum Sabine; 3713.2 mg CAE 100 g-1) and uvaia (Eugenia pyriformis Cambess; 3482.0 mg CAE 100 g-1), re- lating this native fruit to high antioxidant activity, bringing health benefits when introduced in a dietary routine and may contrib- ute to the reduction of chronic non-transmissible diseases.3,20,28,29 An individual composition, guabiroba has high contents of gal- lic acid (3050.8 μg g-1) and epicatechin (5760.4 μg g-1; Table 2), in which phenolic acids and flavonoids are reported to reduce oxidative stress and inflammation, heart diseases, the incidence of type-2 diabetes mellitus (T2DM), in addition to antibacterial, antiproliferative, antioxidant, and anticarcinogenic activities.3,6,30,31

| Table 2. Individual Phenolic Compounds and Carotenoids of Campomanesia xanthocarpa O. Berg Fruits |

|

Compounds

|

Content (unit per 100 g)

|

References

|

|

Phenolic Compounds

|

Gallic acid

|

3050.8 µgb

|

Paulo Farias et al,3

Oliveira Raphaelli et al,6

Santos et al,16

Pereira et al20 |

|

Elagic acid

|

123.6 µgb |

| Ferulic acid |

22.9 µgb

|

|

ρ-coumaric acid

|

15.5 µgb |

| Epicatechin |

5760.4 µgb

|

|

Carotenoids

|

β- carotene

|

123.5 – 3.4×104 µgb |

| α- carotene |

55.5 – 1.7×104 µgb

|

|

Lutein

|

14.9 µga |

| Zeaxanthin |

3.2 µga

|

|

Lycopene

|

0.9 µgb |

|

β-carotene 5,6-epoxide

|

0.8 µga

|

| cryptoxanthin |

12.1 µga

|

|

β- cryptoxanthin

|

93.1 µgb |

| 13-cis-β-carotene |

0.6 µga

|

|

9-cis-β-carotene

|

0.5 µga |

| Violaxanthin |

2.8 µgb

|

| Note: a Values expressed based on dry weight; b Values expressed based on fresh weight. |

From a technological point of view, guabiroba has composition properties that contribute to fruit processing. The moisture (79-83%), the total soluble solids content in the ripe pulp (12-15%), and the total titratable acidity (0.3-0.5%) are in the range recommended for fruits destined for processing, con- tributing to a natural flavor for the product and reducing the ad- dition of sugars, acidulants, and artificial flavors. In addition, the process can be more economical due to the high product yield, a short time in evaporation steps, and less energy expenditures.2,3,20

The high fibers content (6.3-9.7 g 100 g-1; Table 1), in- cluding insoluble and soluble fractions (mainly pectin), are also an important characteristic that can favor the guabiroba processing by the food industries due to the gelling and stabilizing proper- ties, very important for the texture of fruit-based jellies or can- dies.6,7 Dietary fibers are also related to health benefits when rou- tinely consumed, as hypoglycemic, antioxidant, anti-tumor, and anti-inflammatory properties.32,33

The essential oil present in the guabiroba pulp and seeds has a citric flavor and light-yellow color. When compared to oth- er fruits from the same genus, the oil content (0.2%) exceeds 3 times those obtained for Campomanesia adamantium (0.06%) and by 10 times for Campomanesia phaea (<0.02%).2,34,35 In the composi- tion, there are monoterpene hydrocarbons (limonene, α-pinene, o-cimene, β-pinene), most of which are non-toxic to mammals, and can be widely used in artificial flavorings and pharmaceutical formulations due to safety recognition by the United States Food and Drug Administration (U. S FDA). The presence of these compounds in the essential oil also contributes to the use as a flavoring and in alcoholic distillates, ice cream, and sweets.2,36

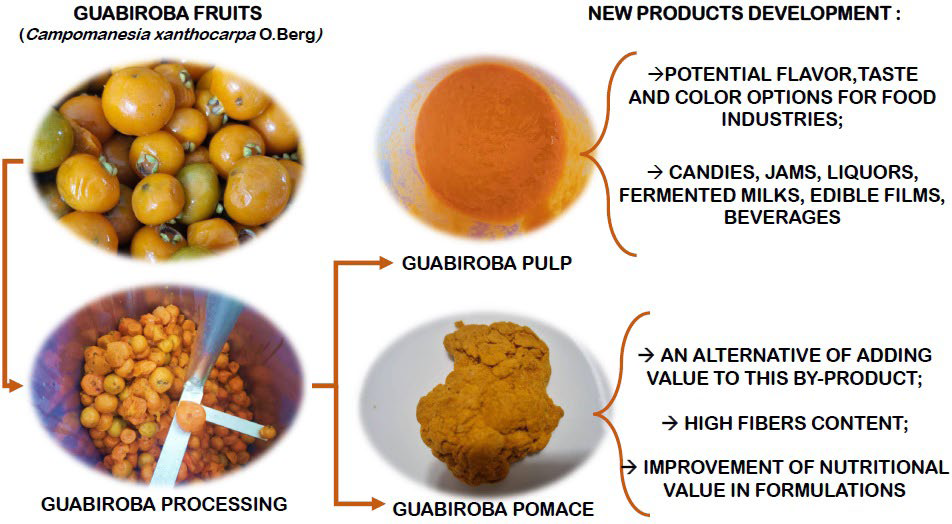

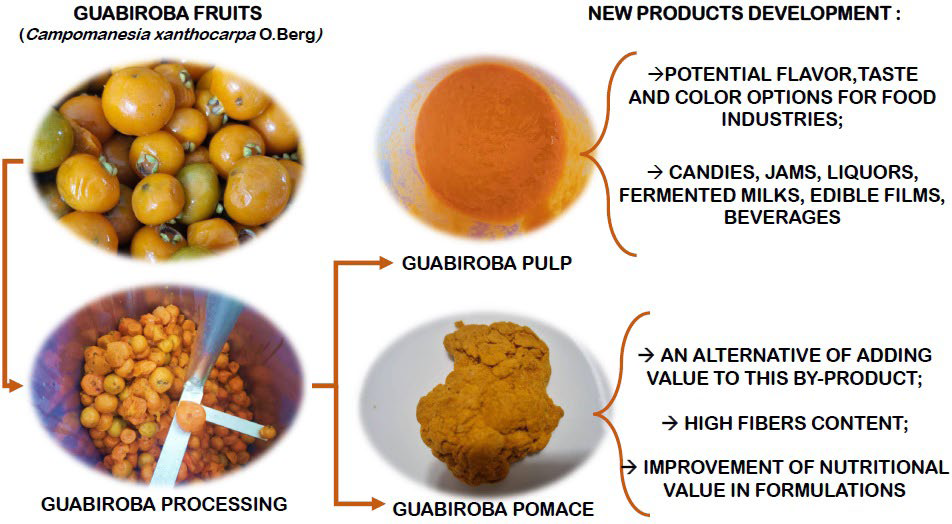

NEW PRODUCTS DEVELOPMENT WITH GUABIROBA

The guabiroba fresh fruit is highly perishable and its original characteristics can be preserved for a maximum of 6-days in refrigerated storage.6,37 The encouragement and application of technologies in fruit processing can increase the demand and commercialization of fresh guabiroba and its products, enable the sustainable development of small rural producers, add value to native fruits (until then unexplored industrially), in addition to enhancing the consumption of new products with potential nutritional and functional value.37

New products development is essential for industrial businesses and interesting for the consumer market. The process- ing of guabiroba fruits represents new and potential aroma, fla- vor, and color options for food industries. The constant search of consumers for new products and lack of interest in traditional products makes the market increasingly competitive, which leads the food industries to search for prominence with the develop- ment of new products (Figure 2).1

Figure 2. The Processing of Guabiroba Fruit to Develop New Products

The use of guabiroba fruits as raw material to produce candies and jams can be an income alternative for rural produc- ers. From the physicochemical properties, which characterize the guabiroba with high moisture, pectin contents, and soluble solids suitable for fruit processing,1,2,16 Santos et al1 developed formula- tions of guabiroba jam (Table 3). The original acidity of the fruits was ideal for conventional jam production (1.2-1.3 g 100 g-1 citric acid), without the need to add acidulants to the formulation. In the traditional jam production (guabiroba pulp, sucrose, and pec- tin), with a long processing time, the vitamin C loss is higher when compared to the jam without added sugar (Vitamin C=97.4% for traditional jams and 113.4-123.7% for diet jams). High tempera- tures can also improve the extraction of phenolic compounds in a short exposure time, releasing free phenolic groups in the middle.38 This explains the higher total phenolic content in guabi- roba jams without added sugar (68.9-72.5 mg gallic acid (GA) 100g-1) where the processing time was lower compared to conven- tional jams (32.2-33.2 mg GA 100 g-1). High antioxidant activities (approximately 45-53 TEAC μMol mL-1, for DPPH radical scav- enging capacity and 23-29 trolox equivalent antioxidant capac- ity (TEAC) μMol mL-1, for 2,2’-azino-bis-3-ethylbenzthiazoline- 6-sulphonic acid (ABTS) radical scavenging capacity), besides being related to phenolic compounds content, they are also as- sociated with total carotenoids, which showed good retention in the formulations (74.8-87.7 β -carotene μg g-1). Guabiroba jams were also produced by Leonarski et al39 who added fructooli- gosaccharides (FOS), with a prebiotic property (Table 3). Even after thermal processing, the jams showed at least 35% of origi- nal bioactive compounds from guabiroba fruit (phenolic com- pounds=466.7-512.0 mg GAE 100 g-1; carotenoids=43.7-51.3 μg β-carotene g-1; and vitamin C=200.3-212.6 mg AA 100 g-1), which enhances this product in the preservation of some functional characteristics, bringing benefits to the consumer’s health. The presence of FOS in the jam formulation, besides contributing to the development of probiotic microorganisms present in the human gut, can modify the jam texture and water retention, since this prebiotic presents OH groups available for bonding with wa- ter molecules, which reduces the rate of water evaporation and forms a thick gel.

| Table 3. Studies about New Products Development with Guabiroba (Campomanesia xanthocarpa O. Berg) |

|

Guabiroba jam

|

Original acidity ideal for jam formulations; high total phenolic content in jams without added sugar (68.9-72.5 mg GA 100 g-1); good retention of total carotenoids (74.8-87.7 β-carotene µg g-1) with high antioxidant activities (approximately 45-53 TEAC µMol mL-1, for DPPH and 23-29 TEAC µMol mL-1 for ABTS).

|

Santos et al1

|

|

Guabiroba jam with prebiotic

|

The presence of FOS (fructo-oligosaccharides) can modify the texture and jam water retention. Even with a heat treatment, the product retained at least 35% of guabiroba bioactive compounds.

|

Leonarski et al39

|

|

Probiotic fermented milk with guabiroba pulp

|

High probiotic counts (8-9 CFU g-1) during the entire simulated gastrointestinal steps, classifying it as a probiotic product. The addition of 10 g 100 g-1 of guabiroba pulp presented higher total phenolic content and antioxidant activity in the gut steps and even in stomach region.

|

Prestes et al10

|

|

Petit Suisse cheese with guabiroba pulp

|

High energy content (92.1 kcal 40 g-1) when compared to commercial products; the original color of the guabiroba pulp influenced the final aspect of the product, with a yellow color. This can help the consumer to associate the fresh fruit with the final product.

|

Messias et al42

|

|

Gluten-free edible film reinforced with guabiroba pulp

|

Guabiroba pulp (10, 15, and 20%) provided films with high resistance to tearing, high thickness and increased biodegradability, with 100% of the films degraded in 45-days.

|

Silva-Rodrigues11

|

|

Edible film with guabiroba pulp for olive oil packaging

|

Guabiroba pulp (20%) provided films with higher water vapor permeability and solubility. The orange color was predominant in the packaging due to the original color of the fruit. In 15-days, olive oil presented peroxide and acidity index below the maximum content allowed by local legislation.

|

Malherbi et al12

|

|

Guabiroba liquor

|

The liqueurs with guabiroba fruit presented low acidity (0.08-0.09 g acid citric 100 mL-1), high pH (4.78-5.28) and high phenolic compounds content (31.62-34.91 mg GAE 100 g-1). The acceptance and purchase intention tests showed a preference for sweet liqueurs (344 gL-1).

|

Leonarski et al43

|

|

Nile tilapia burger with guabiroba peel

|

The addition of 5% guabiroba peel increased the moisture (67.82%), carbohydrate (2.71%), lipid (7.15%), and fibers content (4.43%) of the fish burgers. The results of TBARS showed a potential natural antioxidant activity from guabiroba peel (TBARS≈1.5 mg MDA kg-1, and 1.2 mg MDA kg-1) after 300-days of storage.

|

Cristofel et al45

|

Probiotic fermented milks were developed with the ad- dition of guabiroba pulp by Prestes et al10 and an in vitro gas- trointestinal simulation was performed to evaluate the influence of bioactive compounds from this fruit on the development and survival of probiotic cells throughout the gastrointestinal tract. Before and during the gastric steps, the Bifidobacterium BB-12 count was 8-9 log CFU g-1, which enhanced the product in its pro- biotic characteristics, with a count above the recommended for a probiotic property.40 The addition of 10 g 100 g-1 of guabiroba pulp in the fermented milks showed the highest total phenolic content (TPC) (535.2 mg GAE L-1; 346.0 mg GAE L-1 for the control sample without guabiroba pulp) and antioxidant activi- ties (1,1-diphenyl-2-picrylhydrazyl (DPPH)=1232.0 μmol.L-1 and 516.0 μmol.L-1 for control sample; FRAP=4504.5 μmol.L-1, and 1686.3 μmol.L-1 for control sample) in the gut steps, which is the ideal region for the development of probiotic cells, and even in the extreme pH regions of the stomach (TPC=162.2 mg GAE L-1 and 154.6 mg GAE L-1 for control sample; antioxidant activity: FRAP=1206.4 μmol.L-1, and 358.5 μmol.L-1 for control sample; DPPH=342.0 μmol.L-1 and 82.0 μmol.L-1 for control sample). Phenolic acids and flavonoids from fruits of the Myrtaceae fam- ily have a high molecular weight in a glycosylated form.25 These compounds, in an appropriate concentration, may act as prebiotic and/or protective agents on the bifidobacteria development. In addition, the metabolism of probiotic cells can hydrolyze pheno- lic compounds in simpler forms for microbial absorption through enzymatic activities.41 Thus, the bioactive compounds present in the guabiroba fruit, linked to fermented milk, potentiated this food both in the growth of probiotic cells and in providing a new product with a functional appeal to the consumer market.

Petit Suisse cheeses with this native fruit were produced by Messias et al.42 The guabiroba pulp was added to the formula- tion at a concentration of 20 g 100 g-1 and presented a significant influence on the physicochemical properties of the products. Color parameters characterized the Petit Suisse cheese with a yel- low color (L=71.6; a*=-0.9; b*=31.5; C*=31.5) due to the original color of the pulp, being determinant in the coloring properties of this dairy product. This effect may benefit the consumer to as- sociate the color of the products with the presence of fresh fruit. Concerning the nutritional value, the petit Suisse cheese presented high energy content (92.1 kcal 40 g-1) due to the high carbohy- drate (11.5 g per 40 g), total fat (4.0 g 40 g-1), and protein content (2.7 g 40 g-1). In determining the shelf-life of this product, micro- biological stability was achieved during 28-days at 10 °C, which is considerable time for production, transport, commercial storage, and final consumption of this dairy product. The use of this na- tive fruit to develop a new Petit Suisse cheese flavor becomes rel- evant for new dairy options with a healthy and innovative appeal.

The application of guabiroba fruit can also be an in- novative alternative in the development of active biodegradable packaging since there is a constant incentive to reduce the use of materials from non-renewable sources related to environmental problems. Bioactive compounds and antioxidant properties of guabiroba fruit in the packaging material can act under storage conditions, reduce oxidation reactions, improve the safety and sensory properties of the product, and extend its shelf-life. Mal- herbi et al12 produced a biodegradable active film with guabiroba pulp, corn starch, and gelatin for application as a package for extra-virgin oil. The addition of 10% and 20% guabiroba pulp in the polymer matrix presented an orange color, due to the original carotenoid content in the fruit composition, and a granular tex- ture related to insoluble natural fibers (13.3 g 100 g-1) that did not solubilize in the film-forming solution. Fibers content also can be related, in addition to carbohydrates and protein, to the highest thickness of the films with the addition of 20% guabiroba pulp (0.1243 mm, and 0.0895 mm for the control blend film). These major compounds have a high molecular mass and increased the total solids content in the film solution, which may have contrib- uted to the increase of thickness. However, the presence of origi- nal compounds from fruits, such as sucrose, glucose, maltose, and cellulose can significantly influence the physical barrier properties of the film, due to their high hydrophilic characteristics, increas- ing the solubility (36.92% with 20% pulp, 28.84% with 10% pulp, and 19.78% for control film), and the water vapor permeability (12.95 g mm m-2 d-1 kPa-1 with 20% pulp, 6.75 g mm m-2 d-1 kPa-1 with 10% pulp, and 3.88 g mm m-2 d-1 kPa-1 for control film). In a 15-day storage period of olive oils in polymeric sachets with 10% guabiroba pulp, the peroxide index increased from 6.14 to 8.21 meq kg-1 (for control film and the film with 10% pulp), due to traces of oxygen present at the time of packaging production, while the acidity index remained below 0.1%. These olive oil qual- ity control parameters were below the maximum content allowed by local legislation (20 meq kg-1 and 0.8% oleic acid for peroxide and acidity index, respectively),12 relating the potential antioxidant activity of guabiroba fruits in preserving foods in active packag- ing. Similar behavior was obtained by Silva-Rodrigues et al,11 who also applied guabiroba pulp in the development of gluten-free ed- ible, and functional films (Table 3). The films presented a compact form, without cracks and with excellent mechanical properties due to the high concentration of fibers (6.62%), polysaccharides (8.15% reducing sugars), and other polymeric compounds that can provide a cohesive polymer and result in a film with better rupture stress performance. The natural fibers of guabiroba also are susceptible to degradability, providing films 100% degraded in 45-days.

The original acid/sweet flavor, slight bitterness, and pleasant taste of the guabiroba fruit, in addition to its natural color, become interesting characteristics in the development of beverage blends, which can provide a unique flavor to the prod- uct. For alcoholic beverages, for example, the consumer market is diversified and can provide an important point in the processing of native fruits with new products of high quality and innovative flavor. Leonarski et al43 developed liqueurs from Brazilian native fruits, including the guabiroba (Table 3). Guabiroba blends (2:1; alcohol: fruit) provided liqueurs with 19.0% alcohol content (80 gL-1, dry liqueur) and 21.5% (344 gL-1, sweet liqueur), with values allowed by the Brazilian legislation ( 15 to 54% alcohol content by volume at 20 °C),44 low acidity (0.08-0.09 g acid citric 100 mL-1) and high pH (4.78-5.28). These specific physicochemical proper- ties can provide beverages with highlighted sweetness, pungency and are related to the ripening stage, season, and fruit cultiva- tion. Due to the high contents of phenolic compounds in the natural guabiroba composition (Table 2), the liqueurs presented 31.62-34.91 mg GAE 100 g-1, which can also influence the flavor of the beverages due to pungency and bitter taste, characteristic of some phenolic groups. In addition, antioxidant activities from phenolic compounds can exert antimicrobial properties, reduc- ing the incidence of the proliferation of spoilage microorganisms and increasing the shelf-life of products. The use of native fruits in the development of liqueurs can improve the income of small rural producers, with simple processing, regional fruits, and an increase in added value.43

Antioxidant and functional properties of guabiroba fruit can improve the shelf-life and the nutritional value of foods with high lipid content, which is susceptible to oxidation reac- tions. The use of fruit peels in food formulations, in addition, to containing high amounts of bioactive compounds, may represent an alternative of adding value to this raw material. Cristofel et al45 developed a functional Nile tilapia burger with guabiroba peel, amaranth, and quinoa, to reduce the high lipid oxidation of this fish and increase its shelf-life (Table 3). The addition of 5 g 100 g-1 guabiroba peel provided fish burgers with a lower luminos- ity (45, and 50 for the control burger) and a higher a*parameter (approximately 80, and 78 for the control burger), with a ten- dency to yellow color due to the guabiroba original pigment. The concentration of guabiroba did not significantly affect the water activity (Aw=0.97), and pH (6.4). However, the fruit composition increased the carbohydrate (2.71%, and 1.40% for the control raw burger), lipid (7.15% and 6.14% for the control burger, and fibers content (4.43% and 3.22% for the control burger) of the prod- ucts. Fibers from guabiroba peel also increased the moisture of the product (67.82%, and 67.03% for control raw burger) but did not substantially affect its physical characteristics. The results of thiobarbituric acid reactive substances (TBARS) showed a poten- tial natural antioxidant activity from guabiroba peel (TBARS≈1.5 mg malondialdehyde (MDA) kg-1, and 1.2 mg MDA kg-1 after 300th day of storage), which can prevent lipid oxidation in foods with high lipid content and improve their nutritional value.

Bioactive compounds and the nutritional value from gu- abiroba pulp, peel, seed, or leaves can exert benefits in food for- mulation due to the high natural antioxidant properties that can improve the taste, texture, and reduce oxidative reactions, and mi- crobiological spoilage of the product. These properties can also become potential natural preservatives to reduce, in the future, the use of chemical additives in the development of new food products.

TECHNOLOGIES ALREADY EMPLOYED IN GUABIROBA PROCESSING

Functional aspects of the guabiroba fruit added to its flavor and color characteristics are the aim of recent studies for the extraction and encapsulation of compounds through emerging tech- nologies.46,47,48 Native fruits become an important base for studies due to the innovative and low-cost possibilities of obtaining pig- ments, or bioactive compounds that can be used as natural anti- oxidants and antimicrobials, colorants, and flavoring in the food and pharmaceutical industries.

The extraction of bioactive and thermolabile compounds from fruits can be achieved by non-thermal and environmentally friendly emerging technologies. These processes can extract com- pounds at mild temperatures and/or use safe, available, and low- cost solvents.46,48,49 Czaikoski et al48 obtained natural guabiroba extracts from supercritical CO2 extraction (scCO2), an emerging technique that produces generally recognized as safe (GRAS) ex- tracts in which a high compressible fluid is used as a solvent at low or middle temperature. The extraction performed at 313.15 K (40 °C) and 25 MPa obtained the maximum yield (3.90 wt%; extraction percent: 57.44%), corresponding to the highest pres- sure and lowest temperature evaluated. The extracts presented orange color and chemical composition rich in monoterpene hy- drocarbons (α-eudesmol, β-eudesmol, γ-eudesmol, caryophyllene (E), α-sabinene, β-sabinene, germacrene B, δ-cadinene, humulene and selina-3,7(11)-diene). These compounds from guabiroba oil and extracts contribute to the use of these native fruits as a flavor- ing in beverages, candies, and alcoholic distillates. For antioxidant properties, the extraction at 353.15 K and 25 MPa promoted the highest phenolic content (39.12 mg GAEg-1 of extract), and at the same temperature and 15 MPa, it was obtained the highest antimicrobial activity against Staphylococcus aureus. Bioactive compounds from guabiroba seeds were also extracted by ssCO2 and com- pressed n-butane by Capeletto et al.50 The extracts were obtained at 40 °C and 250 bar for ssCO2, while for n-butane 35 °C and 10 bar. As a solvent, n-butane is cheaper, plenty available, and can be applied at much lower pressures compared to CO2. The extrac- tion yield using ssCO2 was 8.02 wt%, whereas with compressed n-butane 24.71 wt%. Nonpolar solvents, such as the alkanes, are stronger solvents and show faster properties than ssCO2 during the extraction. In the chemical composition, guabiroba seed extracts presented levels of terpenoids, flavonoids, and alkaloids. A higher total phenolic (TPC) and total flavonoids (TFC) con- tent were obtained for the extract from compressed n-butane (TPC=68.58 mg g-1, and 17.18 mg g-1 for ssCO2; TFC=8.10 mg g-1, and 2.31 mg g-1 for ssCO2). Consequently, extracts from com- pressed n-butane showed higher antioxidant activity (≈59% and 50% inhibition of DPPH for ssCO2). Extracts from guabiroba (whole fruit, pulp, or seeds) can be an important natural source of bio compounds with a great interest for food or pharmaceutical industry applications, mainly using emerging technologies with an environmental appeal.

Emerging environment-friendly technologies can also be alternative methods to extract pectin from fruits and replace traditional processes, which require high-temperature processing, large amounts of raw material, and toxic/corrosive solvents, such as nitric, sulfuric, and hydrochloric acids.46,51 The industrial production of pectin is an alternative for adding value to solid re- sides and can potentiate this by-product into an important functional ingredient such as a thickener, gelling agent, texturizer, and emulsifier.52,53 Thus, pressurized hot water extraction (PHWE) is also an efficient “green technology” studied to extract macromolecules from vegetables and fruits.46,54 In this process, the water is maintained under pressure with a temperature between normal boiling point (100 °C) and critical point (374 °C) to keep the wa- ter in the liquid state. This procedure makes the extraction advantageous since this specific water state provides an effective mass transfer, higher solubility of hydrophilic compounds, enhances the diffusion, vapor pressure, and shows low viscosity and surface tension.55,56 In this context and considering the important structural properties of guabiroba composition, Dias et al46 performed a PHWE of pectin from guabiroba fruits at different process conditions. The maximum pectin yield (5.70 wt%, and 5.05 wt% compared to a conventional extraction) was achieved at optimal extraction conditions: 120 °C, a pressure of 150 bar, and a flow rate of 1.5 mL min-1. The pectin yield is related to the increase in temperature and pressure: the thermodynamic properties that can maintain the water in the liquid state and enhance the solubility and diffusion. These physical conditions may facilitate the solvent’s permeability through the cell membrane and improve the polysaccharides extraction that is more adhered to cell walls. The guabiroba pectin from PHWE presented a varied chemi- cal composition (arabinose=44.3-59.7%; galactose=8.9-18.7%; rhamnose=0.6-1.5%; xylose=0.3-1.3%; mannose=0.5-2.8%; glucose=0.5-1.6%; fucose=0.1-0.3%) and an increase of 10.3% in galacturonic acid content compared to traditional hot water extraction (34.8%; traditional extraction=25.7%). This emerging technology is promising to obtain pectin from guabiroba fruits with great characterization and potential to be applied in the food and/or pharmaceutical industries.

On large-scale production, fruit bio compounds have their application limited due to their recurring instability during processing and storage conditions such as potential of hydrogen (pH), temperature, light, interaction with formulation components, oxygen exposure, and during consumer’s digestion (stomach pH, digestive enzymes, inappropriate surrounding, and interaction with other digested nutrients).57 Encapsulation by nanotechnology processes can exert a protective effect on these compounds and improve their solubility, enhancing the functionality and maintaining their bioactivity during processing and even in the digestion steps.47,58 Synthetic polymers, such as polylactic- co-glycolic acid (PLGA) are advantageous due to their reproducibility over natural polymers, higher purity, and safe to be ingest- ed.59 With these promising properties, PLGA nanoparticles were synthesized for delivery of phenolic extracts from guabiroba fruit by Pereira et al.58 A PLGA 50:50 (lactic acid:glycolic acid) ob- tained higher antioxidant activity (378.3 gg-1 for DPPH assay and 229 μmolL-1 TEg-1 for ORAC assay) compared to free guabiroba phenolic extract (GPE) (254.5 gg-1 for DPPH assay and 174.7 μmolL-1 TEg-1 for ORAC assay), with nanoencapsulated extracts related to better protection of guabiroba phenolic compounds during storage. In addition, concentrations around 10 times lower for PLGA (24 μg mL-1) than free GPE (202 μg mL-1) were required to reduce ROS (reactive oxygen species) generation (ap- proximately 100% for PLGA, and 94% for GPE), which is related to be a crucial event in the initiation of cancer cells.60 For antimicrobial activity, a concentration for PLGA (2.67 μg mL-1) around 3 times lower than free GPE (8.11 μg mL-1), showed an improved action against Listeria innocua. Nanoparticles of guabiroba phen lic extracts proved to be an effective method in preserving bioactive extracts until its application and for a prolonged storage.

FUTURE PERSPECTIVES FOR GUABIROBA PROCESSING IN THE FOOD INDUSTRY

The importance of guabiroba biocompounds and their functionality has been the target of studies related to the improvement of antioxidant and antimicrobial activities in both the food and pharmaceutical sectors.10,13,50,61 New technologies may be a potential in the addition of guabiroba (pulp, seed, leaves, peel, and pomace) in formulations to improve the bioactivity of the raw material and enhance the nutritional, functional, and sensory val- ue in the development of new products. High temperatures ap- plied in traditional food processing such as concentration, drying, extraction, pasteurization, or sterilization can affect the bioactiv- ity of fruit phytochemicals, reducing or inactivating their natural benefits in addition to generating unwanted sensory changes with the appearance of off-flavors.

Emerging non-thermal technologies can be applied in guabiroba processing to improve their safety, functionality, and sensory aspects. For food preservation, innovative technologies can be used with promising results. The pulsed electric field is one of the alternatives that have a direct action on microbial cells by applying electrical pulses to the target product, with the achieve- ment of microbiologically safe food and maintaining nutritional and sensory characteristics.62 In fruit and juices, this emerging process is related to improving polyphenols content, vitamins, and ensuring microbiological stability.63,64 Guabiroba products also can be conserved with the use of pulsed light technology, a non-thermal process used for microbial decontamination of sur- faces by short-time pulses of an intense spectrum with ultraviolet C (UV-C) light, which proved to be efficient against mesophilic aerobic cells, Escherichia coli and Pichia fermentans in fruit juices.65,66,67

In the food and pharmaceutical industries, synthetic colorant additives are largely used, however, there are concerns about the addition of these chemical pigments due to adverse health effects. With these facts, natural pigments are encouraged to replace these synthetic ingredients. The yellow/orange color of the guabiroba fruits is a highlight due to its high carotenoids content and this pigment may be a promising replacement in food and pharmaceutical products.17,35,68 High-pressure fluid technologies (HPFT) are consolidated as environment-friendly processes and can be applied from compounds extraction until product formulation.49 Methods including supercritical water ex- traction, pressurized fluid extraction, and supercritical/subcritical CO2 extraction obtained potential results in the extraction of carotenoids from persimmons, and mango peels.69,70 This phytochemical can also be extracted by ultrasound techniques. The ultrasound-assisted extraction (UAE) is a technology that allows the release of high amounts of carotenoids and other bio com- pounds due to the rupture of cell walls by the phenomenon of cavitation. This technology proved to be an efficient method to extract carotenoids from mango with a decrease of wastewater, faster release, and extraction of this phytochemical with reducing operating temperatures.71

The concentration of carotenoids and other phytochemicals from guabiroba fruits can also potentially be performed by techniques that employ the use of low temperatures, preserving most of the original compounds, such as the freeze concentration, an unconventional concentration process in which liquid foods are concentrated over a pre-freezing step followed by the separation of pure ice crystals, proved to be an efficient technique to concentrate juices from different fruits with high amounts of bioactive compounds.72,73,74,75

For future applications in high demand in the food industry, studies on the guabiroba fruit must be constantly encouraged to expand knowledge about the properties of this Brazilian fruit to different parts of the globe. The valorization of the guabiroba associated with emerging technologies can reduce the loss of functional properties of this fruit, generate several opportunities for rural producers, new choices for the industrial sector, and new functional/nutritive products for the consumer market.

CONCLUSION

Guabiroba (Campomanesia xanthocarpa O. Berg) is a native fruit that is consolidated by several recent studies about its high fiber and carbohydrates content, polyphenols, carotenoids, and vitamin C. These nutritional and functional properties enhance this fruit for application in the food and pharmaceutical sectors. However, due to its regional and little widespread knowledge, guabiroba is not a fruit intended for processing on a large scale, only with home- made jams, candies, and liqueurs by rural producers. Promising results of recent researches increase the benefits of guabiroba inserted in the formulation of new products, in the barrier prop- erties of biodegradable packaging, and its potency as a prebiotic agent. Furthermore, emerging non-thermal technologies are con- stantly being improved to increase their effectiveness in extract- ing fruit compounds and applying a new product, being able to associate environmentally friendly processes with increased qual- ity and retention of most bioactive compounds. The potential technological approach of guabiroba showed in this review can boost the development of effective processes for the extraction and processing of fruits and by-products, enriching the formula- tion of new products and increasing the added value of this na- tive Brazilian fruit, hitherto unexplored by large industries.

FUNDING

The National Council for Scientific and Technological Develop- ment (CNPq, Brazil) [CNPq, 405965/2016-8], and the Coordina- tion of Improvement of Higher Education Personnel (CAPES, Brazil) [001].

ACKNOWLEDGMENTS

The authors are grateful to National Council for Scientific and Technological Development (CNPq, Brazil) for the financial sup- port [CNPq, 405965/2016-8], and to the Coordination of Im- provement of Higher Education Personnel (CAPES, Brazil) by the scholarship [001].

DATA AVAILABILITY STATEMENT

Data sharing does not apply to this article as no new data were created or analysed in this study.

CONFLICTS OF INTEREST

The authors declare that they have no conflicts of interest.