1. Fox PF. History of dairy chemistry. In: Fuquay JW, Fox PF, Mcsweeney PLH, eds. Encyclopedia of Dairy Sciences, 2nd ed. Cambridge, Massachusetts, USA: Academic Press; 2011: 18-25.

2. Damodaran S. Aminoácido S, Peptídeos E Proteínas. In: Damodaran S, Parkin KL, Fennema OR, eds. Química De Alimentos De Fennema, 4th ed. Porto Alegre, Canada: Artmed; 2010.

3. Foegeding EA, Davis JP, Doucet D, Mcguffey MK. Advances in modifying and understanding whey protein functionality. Trends in Food Science and Technology. 2002; 13: 151-159. doi: 10.1016/S0924-2244(02)00111-5

4. Steinhauer T, Kühnl W, Kulozik U. Impact of protein interactions and transmembrane pressure on physical properties of filter cakes formed during filtrations of skim milk. Procedia Food Science. 2011; 1: 886-892. doi: 10.1016/j.profoo.2011.09.134

5. Fox PF, Mcsweeney PLH. Milk proteins. In: Fox PF, McSweeney PLH. eds. Dairy Chemistry and Biochemistry. New York, USA: Blackie Academic & Professional; 1998: 146-237.

6. Farrell HM. Casein nomenclature, structure, and association. In: Fuquay JW, Fox PF, Mcsweeney PLH, eds. Encyclopedia of Dairy Sciences. 2nd ed. Cambridge, Massachusetts, USA: Academic Press; 2011: 765-771.

7. Walstra P, Wouters JT, Geurts TJ. Dairy Science and Technology. 2nd ed. Oxfordshire, UK: Taylor & Francis Group; 2006.

8. Burton H. Ultra-High-Temperature Processing of Milk and Milk Products. New York, USA: Elsevier Applied Science Publishers; 1988.

9. Mottar J, Naudts M. La qualité du lait chauffé à ultrahaute température comparée à celle du lait pasteurisé et stérilisé dans la bouteille. Lait. 1979; 59: 476-488. doi: 10.1051/lait:197958823

10. Burton, H. Reviews of the progress of dairy science: the bacteriological, chemical, biochemical and physical changes that occur in milk at temperatures of 100-150 degrees C. Journal of Dairy Research. 1984; 51: 341-363. doi: 10.1017/S002202990002361X

11. Cheeseman GC, Knight DC. The nature of casein aggregates in heated and stored milk. Journal of Dairy Research. 1974; 41: 359-366. doi: 10.1017/S0022029900019804

12. Douglas FW, Greenberg Jr. R, Farrell Jr, HM, Edmondson LF. Effects of ultra-high-temperature pasteurization on milk proteins. Journal of Agricultural and Food Chemistry. 1981; 29: 11-15. doi: 10.1021/jf00103a004

13. Singh H, Latham JM. Heat stability of milk: Aggregation and dissociation of protein at ultra-high temperatures. International Dairy Journal. 1993; 3: 225-237. doi: 10.1016/0958-6946(93)90066-9

14. Cosio MS, Mannino S, Buratti S. Electrochemical sensor detecting free sulfhydryl groups: Evaluation of milk heat treatment. J Dairy Sci. 2000; 83: 1933-1938. doi: 10.3168/jds.S0022-0302(00)75068-5

15. Elliott AJ, Datta N, Amenu B, Deeth HC. Heat-induced and other chemical changes in commercial UHT milks. J Dairy Res. 2005; 72: 442-446. doi: 10.1017/S002202990500138X

16. Pellegrino L, De Noni I, Resmini P. Coupling of lactulose and furosine indices for quality evaluation of sterilized milk. International Dairy Journal. 1995; 5: 647-659. doi: 10.1016/0958-6946(95)00036-3

17. Borcherding K, Lorenzen PC, Hoffmann W, Schrader K. Effect of foaming temperature and varying time/temperature conditions of pre-eating on the foaming properties of skimmed milk. International Dairy Journal. 2008; 18: 349-358. doi: 10.1016/j.idairyj.2007.11.016

18. Krasaekoopt W, Bhandari B, Deeth H. Yogurt from UHT milk: A review. Australian Journal of Dairy Technology. 2003; 58: 26-29.

19. Parnell-Clunies E, Kakuda Y, Deman JM, Cazzola F. Gelation profiles of yogurt as affected by heat treatment of milk. J Dairy Sci. 1988; 71: 582-588. doi: 10.3168/jds.S0022-0302(88)79594-6

20. Wang Q, Bulca S, Kulozik U. A comparison of low-intensity ultrasound and oscillating rheology to assess the renneting properties of casein solutions after UHT heat pre-treatment. International Dairy Journal. 2007; 17: 50-58. doi: 10.1016/j.idairyj.2005.12.008

21. Al-Akoum O, Ding LH, Jaffrin MY. Microfiltration and ultrafiltration of UHT skim milk with a vibrating membrane module. Separation and Purification Technology. 2002; 28: 219-234. doi: 10.1016/S1383-5866(02)00076-X

22. Amornkul Y, Henning DR. Utilization of microfiltration or lactoperoxidase system or both for manufacture of cheddar cheese from raw milk. J Dairy Sci. 2007; 90: 4988-5000. doi: 10.3168/jds.2007-0281

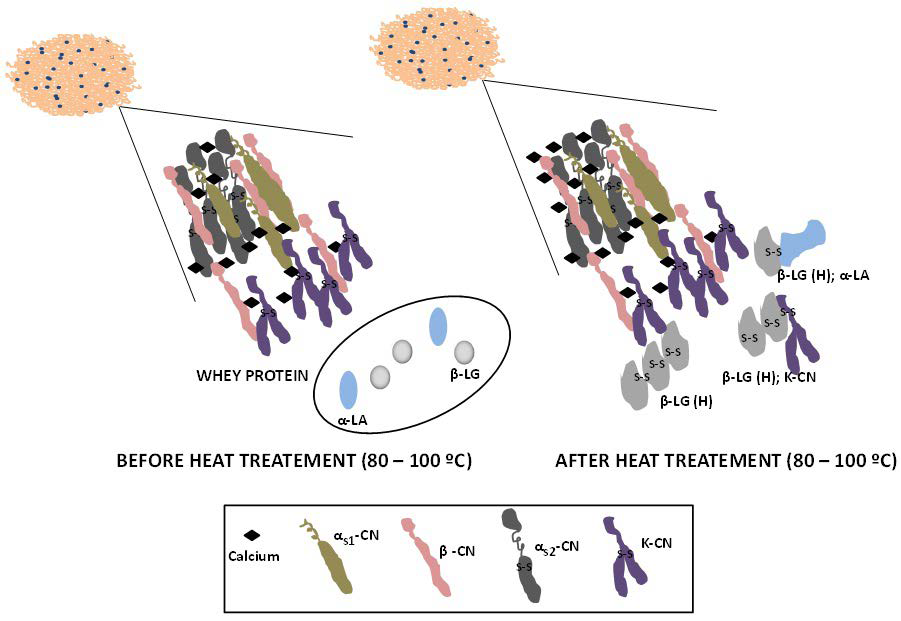

23. Carvalho AF, Maubois JL. Applications of membrane technologies in the dairy industry. In: Coimbra JSR, Teixeira JA, eds. Engineering Aspects of Milk and Dairy Products. Boca Raton, Florida, USA: CRC Press; 2009: 33-56.

24. Elwell MW, Barbano DM. Use of microfiltration to improve fluid milk quality. J Dairy Sci. 2006; 89: 20-30. doi: 10.3168/jds.S0022-0302(06)72361-X

25. Fritsch J, Moraru CI. Development and optimization of carbon dioxideaided cold microfiltration process for the physical removal of microorganisms and somatic cells from skim milk. J Dairy Sci. 2008; 91: 3744-3760. doi: 10.3168/jds.2007-0899

26. Larsen PH. Microfiltration for pasteurised milk. In: Fox PF, ed. Heat Treatments and Alternative Methods. Belgium: International Dairy Federation; 1995: 232-239.

27. Meershon M. Nitrate free cheesemaking with bactocatch. North European Food Dairy Journal. 1989; 55: 108-113.

28. Saboya LV, Maubois JL. Current developments of microfiltration technology in the dairy industry. Lait. 2000; 80: 541-553. doi: 10.1051/lait:2000144

29. Trouve E, Maubois JL, Piot M, et al. Rètention de différentesespécesmicrobienneslors de l’epuration du lait par microfiltration en flux tangentiel. Lait. 1991; 71: 1-13. doi: 10.1051/lait:199111

30. Amelia I, Barbano DM. Production of an 18% protein liquid micellar casein concentrate with a long refrigerated shelf life. J Dairy Sci. 2013; 96: 3340-3349. doi: 10.3168/jds.2012-6033

31. Brans G, Schroën CGPH, Van Der Sman RGM, Boom RM. Membrane fractionation of milk: State of the art and challenges. Journal of Membrane Science. 2004; 243: 263-272. doi: 10.1016/j.memsci.2004.06.029

32. Papadatos A, Neocleous M, Berger AM, Barbano DM. Economic feasibility evaluation of microfiltration of milk prior to cheesemaking. J Dairy Sci. 2003; 86: 1564-1577. doi: 10.3168/jds.S0022-302(03)73742-4

33. Messens W, Camp V, Huyghebaert A. The use of high pressure to modify the functionality of food proteins. Trends in Food Science and Technology. 1997; 8: 107-112. doi: 10.1016/S0924-2244(97)01015-7

34. Foegeding EA, Davis JP. Food protein functionality: A comprehensive approach. Food Hydrocolloids. 2011; 25: 1853-1864. doi: 10.1016/j.foodhyd.2011.05.008

35. Swaisgood HE. Características do leite. In: Damodaran S, Parkin KL, Fennema OR, eds. Química De Alimentos De Fennema. 4th ed. Porto Alegre: Artmed. 2010.

36. De Kruif CG, Huppertz T, Urban VS, Petukhov AV. Casein micelles and their internal structure. Adv Colloid Interface Sci. 2012; 171: 36-52. doi: 10.1016/j.cis.2012.01.002

37. De Kruif CG, Holt C. Casein micelle structure, functions and interactions. In: Fox PF, McSweeney PLH, eds. Advanced Dairy Chemistry. 3rd ed. New York, USA: Kluwer Academic/Plenum Publishers; 2003: 233-276. doi: 10.1007/978-1-4419-8602-3_5

38. Swaisgood HE. Symposium: Genetic perspectives on milk proteins: Comparative studies and nomenclature. Review and update of casein chemistry. J Dairy Sci. 1993; 76: 3054-3060.

39. Raikos V. Effect of heat treatment on milk protein functionality at emulsion interfaces: A review. Food Hydrocolloids. 2010; 24: 259-265. doi: 10.1016/j.foodhyd.2009.10.014

40. Baier D, Schmitt C, Knorr D. Effect of high pressure – low temperature processing on composition and colloidal stability of casein micelles and whey proteins. International Dairy Journal. 2015; 43: 51-60. doi: 10.1016/j.idairyj.2014.11.008

41. Crowley P, O’Brien CM, Slattery H, Chapman D, Arendt EK, Stanton C. Functional properties of casein hydrolysates in bakery applications. European Food Research and Technology. 2002; 215: 131-137. doi: 10.1007/s00217-002-0510-5

42. Erdem YK. Modification of casein micelle structure caused by ultrafiltration and heat treatment: A spectrofluorimetric and kinetic approach. Journal of Food Engineering. 2006; 74: 536-541. doi: 10.1016/j.jfoodeng.2005.03.041

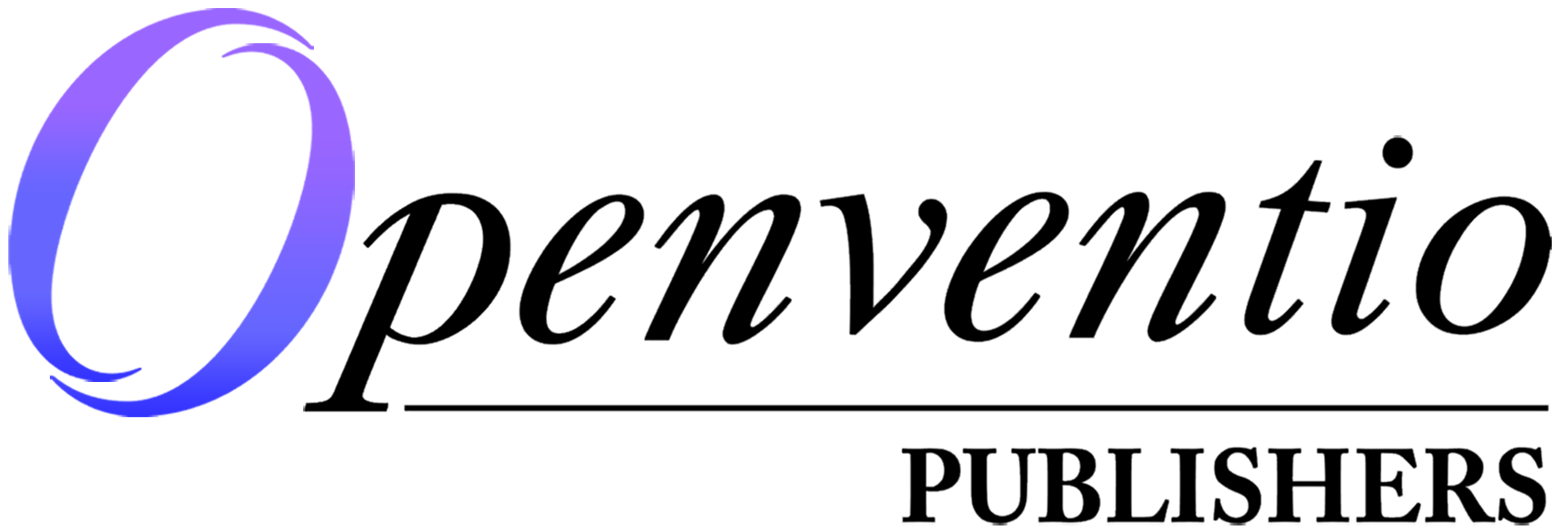

43. Considine T, Patel HA, Anema SG, Singh H, Creamer LK. Interactions of milk proteins during heat and high hydrostatic pressure treatments – A review. Innovative Food Science and Emerging Technologies. 2007; 8: 1-23. doi: 10.1016/j.ifset.2006.08.003

44. Kuwajima K, Ikeguchi M, Sugawara T, Hiraoka Y, Sugai S. Kinetics of disulfide bond reduction in α-lactalbumin by dithiothreitol and molecular basis of superreactivity of the cys6-cys120 disulfide bond. Biochemistry. 1990; 29: 8240-8249. doi: 10.1021/bi00488a007

45. Wijayanti HB, Bansal N, Deeth HC. Stability of whey proteins during thermal processing: A review. Comprehensives Reviews in Food Science and Food Safety. 2014; 13: 1235-1251. doi: 10.1111/1541-4337.12105

46. Angel CR, Dalgleish DG. Structures and some properties of soluble protein complexes formed by the heating of reconstituted skim milk powder. Food Research International. 2006; 39: 472-479. doi: 10.1016/j.foodres.2005.09.010

47. Gani A, Broadway AA, Ahamd M, et al. Effect of whey and casein protein hydrolysates on rheological, textural and sensory properties of cookies. J Food Sci Technol. 2014; 35: 1-9. doi: 10.1007/s13197-014-1649-3

48. Singh H, Waungana A. Influence of heat treatment of milk on cheesemaking properties. International Dairy Journal. 2001; 11: 543-551. doi: 10.1016/S0958-6946(01)00085-1

49. Nicorescu I, Loisel C, Vial C, et al. Combined effect of dynamic heat treatment and ionic strength on the properties of whey protein foams – Part II. Food Research International. 2008; 41:980-988. doi: 10.1016/j.foodres.2008.08.003

50. Jelen P, Rattray W. Thermal denaturation of whey proteins. In: Fox PF, ed. Heat-Induced Changes in Milk. 2nd ed. Belgium: International Dairy Federation; 1995: 66-85.

51. Pellegrino L, Cattaneo S, De Noni I. Effects of processing on protein quality of milk and milk products. In: Fuquay JW, Fox PF, Mcsweeney PLH, eds. Encyclopedia of Dairy Sciences. 2nd ed. Cambridge, Massachusetts, USA: Academic Press; 2011: 226-234.

52. Kinsella JE. Relationships between structure and functional properties of food proteins. In: Fox PF, Condon JJ. Food Proteins. New York, USA: Applied Science; 1982: 51-103.

53. Corredig M, Dalgleish DG. Effect of different heat treatments on the strong binding interactions between whey proteins and milk fat globules in whole milk. Journal of Dairy Research. 1996; 63: 441-449. doi: 10.1017/S0022029900031940

54. Jeanson S, Dupont D, Grattard N, Rolet-Répécaud O. Characterization of the heat treatment undergone by milk using two inhibition ELISAs for quantification of native and heat denatured α-Lactalbumin. J Agric Food Chem. 1999; 47: 2249-2254. doi: 10.1021/jf9809232

55. Patel HA, Singh H, Anema SG, Creamer LK. Effects of heat and high hydrostatic pressure treatments on disulfide bonding interchanges among the proteins in skim milk. J Agric Food Chem. 2006; 54: 3409-3420. doi: 10.1021/jf052834c

56. Dannenberg F, Kessler HG. Reaction kinetics of the denaturation of whey proteins in milk. Journal of Food Science. 1998; 53:258-263. doi: 10.1111/j.1365-2621.1988.tb10223.x

57. Oldfield DJ, Singh H, Taylor MW, Pearce KN. Kinetics of denaturation and aggregation of whey proteins in skim milk heated in an ultra-hight temperature (UHT) pilot plant. International Dairy Journal. 1998; 8: 311-318. doi: 10.1016/S0958-6946(98)00089-2

58. Singh H, Creamer LK. Heat stability of milk. In: FOX PF. Advanced Dairy Chemistry. 2nd ed. Barking, London: Elsevier Applied Science; 1992: 621-656.

59. Wolfschoon-Pombo AF, Fernandes RM, Granzinolli GGM. Efeitos da pasteurizacao-HTST e da fervura domestica sobre a proteína do leite [In: French]. Revista do Instituto de Laticínios Cândido Tostes. 1982; 37: 3-7.

60. Claeys WL, Ludikhuyze LR, Van Loey AM, Hendrickx ME. Inactivation kinetics of alkaline phosphatase and lactoperoxidase, and denaturation kinetics of β-lactoglobulin in raw milk under isothermal and dynamic temperature conditions. J Dairy Res.2001; 68: 95-107. doi: 10.1017/S002202990000460X

61. Oldfield DJ, Singh H, Taylor MW. Association ofβ-lactoglobulin and α-lactalbumin whit the casein micelles in skim milk heated in an ultra-hight temperature plant. International Dairy Journal. 1998; 8: 765-770. doi: 10.1016/S0958-6946(98)00127-7

62. Walkling-Ribeiro M, Rodríguez-González O, Jayaram S, Griffiths MW. Microbial inactivation and shelf life comparison of ‘cold’ hurdle processing with pulsed electric fields and microfiltration, and conventional thermal pasteurisation in skim milk. Int J Food Microbiol. 2011; 144: 379-386. doi: 10.1016/j.ijfoodmicro.2010.10.023

63. Hoffmann W, Kiesner C, Clawin-Raedecker I, et al. Processing of extended shelf life milk using microfiltration. International Journal of Dairy Technology. 2006; 59: 229-235. doi: 10.1111/j.1471-0307.2006.00275.x

64. Kaufmann V, Kulozik U. Kombination von mikrofiltration und thermischen verfahrenzur haltbarkeits verlängerung von lebensmitteln. Chemie Ingenieur Technik. 2006; 78: 1647-1654. doi: 10.1002/cite.200600094

65. Fernández García L, Álvarez Blanco S, Riera Rodríguez FA. Microfiltration applied to dairy streams: Removal of bacteria. J Sci Food Agric. 2013; 93(2): 187-196. doi: 10.1002/jsfa.5935

66. Fromm HI, Boor KJ. Characterization of pasteurized fluid milk shelf-life attributes. Journal of Food Science. 2004; 69: 207-214. doi: 10.1111/j.1365-2621.2004.tb09889.x

67. Barbano DM, Ma Y, Santos MV. Influence of raw milk quality on fluid milk shelf life. J Dairy Sci. 2006; 89 Suppl 1: E15-19. doi: 10.3168/jds.S0022-0302(06)72360-8

68. Gesan-Guiziou G. Removal of bacteria, spores and somatic cells from milk by centrifugation and microfiltration techniques. In: Griffiths MW, ed. Improving the Safety and Quality of Milk. Sawston, Cambridge: Woodhead Publishing; 2010: 349-372. doi: 10.1533/9781845699420.4.349

69. Pouliot Y. Membrane processes in dairy technology—From a simple idea to worldwide panacea. International Dairy Journal. 2008; 18: 735-740. doi: 10.1016/j.idairyj.2008.03.005

70. Baker RW. Membrane Technology and Applications. 2nd ed. New York, USA: John Wiley and Sons; 2004: 538.

71. Rosenberg M. Current and future applications for membrane processes in the dairy industry. Trends in Food and Technology. 1995; 6: 12-19. doi: 10.1016/S0924-2244(00)88912-8

72. Wiston WS, Sirkar KK. Membrane Handbook. New York, USA: Springer Publishers; 1992: 3-16.

73. Avalli A, Povolo M, Carminati D, Contarini GA. Significance of 2-heptanone in evaluating the effect of microfiltration/pasteurisation applied to goats’ milk. International Dairy Journal. 2004; 14: 915-921. doi: 10.1016/j.idairyj.2004.03.004

74. Azzara CD, Dimick PS. Lipoprotein lipase activity of milk from cows with prolonged subclinical mastitis. J Dairy Sci. 1985; 68: 3171-3175. doi: 10.3168/jds.S0022-0302(85)81223-6

75. Ma Y, Ryan C, Barbano DM, et al. Effects of somatic cell count on quality and shelf-life of pasteurized fluid milk. J Dairy Sci. 2000; 83: 264-274. doi: 10.3168/jds.S0022-0302(00)74873-9

76. Te Giffel MC, Van Der Horst HC. Comparison between bactofugation and microfiltration regarding efficiency of somatic cell and bacteria removal. Bulletin of the International Dairy Federation. 2004; 389: 49-53.

77. Verdi RJ, Barbano DM. Preliminary investigation of the properties of somatic cell proteases. J Dairy Sci. 1988; 71: 534-538. doi: 10.3168/jds.S0022-0302(88)79586-7

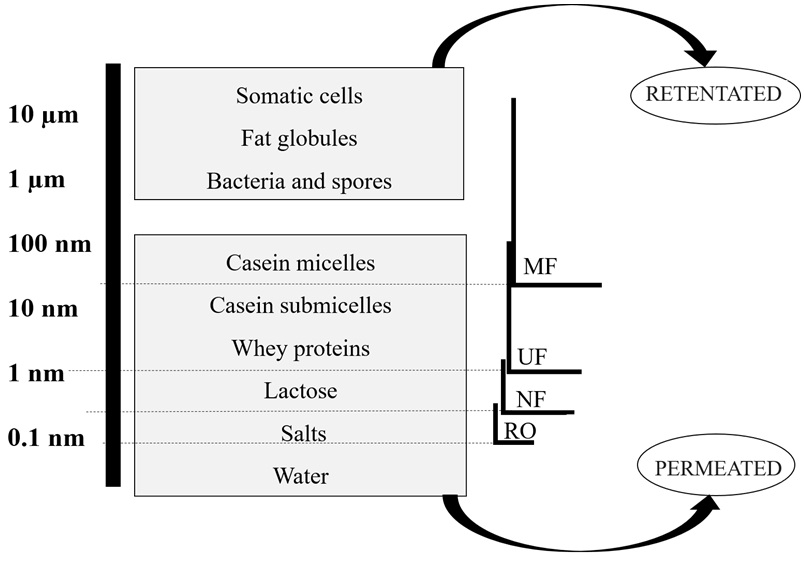

78. Tan TJ, Wang D, Moraru CI. A physicochemical investigation of membrane fouling in cold microfiltration of skim milk. J Dairy Sci. 2014; 97(8): 4759-4771. doi: 10.3168/jds.2014-7957

79. Fuente EBL, Torrestiana-Sanchez B, Martínez-Gonzalez E, Mainou-Sierra JM. Microfiltration of whole milk with silicon microsieves: Effect of process variables. Chemical Engineering Research and Design. 2010; 88: 653-660. doi: 10.1016/j.cherd.2009.09.014

80. James BJ, Jing Y, Chen XD. Membrane fouling during filtration of milk—A microstructural study. Journal of Food Engineering. 2003; 60: 431-437. doi: 10.1016/S0260-8774(03)00066-9

81. Dickinson, E. Adsorbed protein layers at fluid interfaces: Interactions, structure and surface rheology. Colloids and Surfaces B: Biointerfaces. 1999; 15: 161-176. doi: 10.1016/S0927-7765(99)00042-9

82. Nakanishi K, Sakiyama T, Imamura K. On the adsorption of proteins on solid surfaces, a common but very complicated phenomenon. J Biosci Bioeng. 2001; 91(3): 233-244. doi: 10.1016/S1389-1723(01)80127-4

83. Fane AG, Chang S. Techniques to enhance performance of membrane processes. In: Pabby AK, Rizvi SSH, Sastre AM. Handbook of Membrane Separations: Chemical, Pharmaceutical, Food, and Biotechnological Applications. Boca Raton, Florida: CRC Press; 2009: 193-232.

84. Gesan-Guiziou G, Boyaval E, Daufin G. Critical stability conditions in crossflow microfiltration of skim milk: Transition to irreversible fouling. Journal of Membrane Science. 1999; 158: 211-222. doi: 10.1016/S0376-7388(99)00017-4

85. Wang K, Zhou C, HongY, Zhang X. A review of protein adsorption on bioceramics. Interface Focus. 2012; 2: 259-277. doi: 10.1098/rsfs.2012.0012

86. Gao N, Li M, Jing W, Fan Y, Xu N. Improving the filtration performance of ZrO2 membrane in non-polar organic solvents by surface hydrophobic modification. Journal of Membrane Science. 2011; 375: 276-283. doi: 10.1016/j.memsci.2011.03.056

87. Chandavarkar AS. Dynamics of fouling of microporous membranes by proteins. United States. Massachusetts Institute of Technology. 1990; 274-284.

88. Kim KJ, Chen V, Fane AG. Some factors determining protein aggregation during ultrafiltration. Biotechnol Bioeng. 1993; 42: 260-265. doi: 10.1002/bit.260420216

89. Jaspe J, Hagen SJ. Do protein molecules unfold in a simple shear flow? Biophys J. 2006; 91: 3415-3424. doi: 10.1529/biophysj.106.089367

90. Kelly ST, Opong WS, Zydney AL. The influence of protein aggregates on the fouling of microfiltration membranes during stirred cell filtration. Journal of Membrane Science. 1993; 80: 175-187. doi: 10.1016/0376-7388(93)85142-J

91. Kelly ST, Zydney AL. Effects of intermolecular thiol–disulfide interchange reactions on BSA fouling during microfiltration. Biotechnol Bioeng. 1994; 44: 972-982. doi: 10.1002/bit.260440814

92. Kelly ST, Zydney AL. Mechanisms for BSA fouling during microfiltration. Journal of Membrane Science. 1995; 107: 115-127. doi: 10.1016/0376-7388(95)00108-O

93. Kelly ST, Zydney AL. Protein fouling during microfiltration: Comparative behavior of different model proteins. Biotechnol Bioeng. 1997; 55: 91-100. doi: 10.1002/(SICI)1097- 0290(19970705)55:1<91::AID-BIT11>3.0.CO;2-6

94. Wit JN. Thermal behaviour of bovine β-lactoglobulin at temperatures up to 150C. A review. Trends in Food Science Technology. 2009; 20: 27-34. doi: 10.1016/j.tifs.2008.09.012

95. Barbut S, Foegeding EA. Ca2+ -induced gelation of pre-heated whey protein isolate. Journal of Food Science. 1993; 58: 867-871. doi: 10.1111/j.1365-2621.1993.tb09379.x

96. Xiong YL, Dawson KA, Wan L. Thermal aggregation of β-lactoglobulin: Effect of pH, ionic environment, and thiol reagent. J Dairy Sci. 1993; 76: 70-77. doi: 10.3168/jds.S0022-0302(93)77324-5

97. Marshall AD, Munro PA, Trägårdh G. Influence of ionic calcium concentration on fouling during the cross-flow microfiltration of β-lactoglobulin solutions. Journal of Membrane Science. 2003; 217: 131-140. doi: 10.1016/S0376-7388(03)00085-1

98. Edwards PB, Creamer LK, Jameson GB. Structure and stability of whey proteins. In: Boland M, Singh H, Thompson A. Milk Proteins. Amsterdam, Netherlands: Elsevier; 2008: 163-203.

99. Kühnl W, Piry A, Kaufmann V, Grein T, Ripperger S, Kulozik U. Impact of colloidal interactions on the flux in cross-flow microfiltration of milk at different pH values: A surface energy approach. Journal of Membrane Science. 2010; 352: 107-115. doi: 10.1016/j.memsci.2010.02.006

100. Svanborg S, Johansen AG, Abrahamsen RK, Skeie SB. Initial pasteurization effects on the protein fractionation of skimmed milk by microfiltration. International Dairy Journal. 2014; 37: 26-30. doi: 10.1016/j.idairyj.2014.02.004

101. McMahon DJ, Paulson B, Oberg CJ. Influence of calcium, pH, and moisture on protein matrix structure and functionality in direct-acidified nonfat Mozzarella cheese. J Dairy Sci. 2005; 88: 3754-3763. doi: 10.3168/jds.S0022-0302(05)73061-7

102. Kaombe DD, Du YH, Lewis MJ. Mineral partitioning in milk and milk permeates at high temperature. J Dairy Res. 2012; 79: 1-6. doi: 10.1017/S0022029911000616

103. Morison KR, Mackay FM. Viscosity of lactose and whey protein solutions. International Journal of Food Properties. 2001; 4: 441-454. doi: 10.1081/JFP-100108647

104. Hurt EE, Adams MC, Barbano DM. Microfiltration of skim milk and modified skim milk using a 0.1-µm ceramic uniform transmembrane pressure system at temperatures of 50, 55, 60, and 65 °C. J Dairy Sci. 2015; 98(2): 765-780. doi: 10.3168/jds.2014-8775

105. Long JE, Van Winkle Q, Gould JA. Heat-induced interaction between crude κ-casein and β-lactoglobulin. J Dairy Sci. 1963; 46: 1393-1396. doi: 10.3168/jds.S0022-0302(63)89276-0

106. Dalgleish DG, Senaratne V, Francois S. Interactions between α-lactalbumin and β-lactoglobulin in the early stages of heat denaturation. Journal of Agricultural and Food Chemistry. 1997; 45:3459-3464. doi: 10.1021/jf970113a

107. Moro A, Gatti C, Delorenzi N. Hydrophobicity of whey protein concentrates measured by fluorescence quenching and its relation with surface functional properties. J Agric Food Chem. 2001; 49: 4784-4789. doi: 10.1021/jf001132e

108. Wu X, Narsimhan G. Characterization of secondary and tertiary conformational changes of beta-lactoglobulin adsorbed on silica nanoparticle surfaces. Langmuir. 2008; 24: 4989-4998. doi: 10.1021/la703349c

109. Steinhauer T, Schwing J, Krauß S, Kulozik U. Enhancement of ultrafiltration performance and improvement of hygienic quality during the production of whey concentrates. International Dairy Journal. 2015; 45: 8-14. doi: 10.1016/j.idairyj.2015.01.010

110. Marshall AD, Munro PA, Trägårdh G. Influence of permeate flux on fouling during the microfiltration of β-lactoglobulin solutions under cross-flow conditions. Journal of Membrane Science. 1997; 130: 23-30. doi: 10.1016/S0376-7388(97)00004-5

111. Mourouzidis-Mourouzis S, Karabelas A. Whey protein fouling of microfiltration ceramic membranes—pressure effects. Journal of Membrane Science. 2006; 282: 124-132. doi: 10.1016/j.memsci.2006.05.012

112. Mourouzidis-Mourouzis S, Karabelas A. Whey protein fouling of large poresize ceramic microfiltration membranes at small cross-flow velocity. Journal of Membrane Science. 2008; 323: 17-27. doi: 10.1016/j.memsci.2008.05.053

113. Pinto MS, Pires ACS, Sant’ana HMP, Soares NFF, Carvalho AF. Influence of multilayer packaging and microfiltration process on milk shelf life. Food Packaging and Shelf Life. 2014; 1: 151-159. doi: 10.1016/j.fpsl.2014.01.006

114. Lewis M. Improving pasteurized and extended shelf-life milk. In: Griffiths MW, ed. Improving the Safety and Quality of Milk. Sawston, Cambridge: Woodhead Publishing; 2010: 277-301. doi: 10.1533/9781845699420.4.277