INTRODUCTION

In the dairy industry, fermentation yields miscellaneous conventional and commercial milk products, being prepared and consumed by people in various parts around the globe.1 From a nutritional point of view, fermented products boost diet and are advantageous providing numerous health promoting elements.2,3 These products favorably supplement the diet and provide elements vital for growth and good health. On account of therapeutic and nutritional significance, there is a rising interest towards productivity of goat milk.4 Goat milk producers throughout the world are adopting value adding strategies to produce a variety of products.4,5 Owing to their conspicuous potentiality, different products obtained from goat milk have beneficial aspects in medicinal and nutritional domains.6 Additionally, goat milk is preferable to cow milk owing to essentials nutrients it provides to infants and the substantial therapeutic role.7

Yoghurt spread is a concentrated yoghurt; a vital source of protein having thick consistency (21-26% total solids and 9-11% fat proportion). It encompasses a multitude of minerals e.g. phosphorus, zinc, molybdenum, iodine, calcium, potassium as well as vitamins and crude protein.8 Anciently, it was manufactured by straining milk set yoghurt for whey removal and cloth bags were normally used for this purpose.9 In recent times, certain improved strategies such as ultrafiltration and centrifugation have replaced the conventional mechanism at industrial level. The taste of yoghurt spread is very similar to that of sour cream and cottage cheese owing to the release of diacetyl during fermentation that imparts a particular strong flavor to it.10 It can be stored and utilized within two-weeks of production; however, shelf life can be extended up to two-years via supplementation of different oils as they modify sensorial attributes and enhance palatability.11

There is a strong link between the consumption of lipids and various heart diseases such as chronic heart disease (CHD), cancer and depression. To overcome this issue, food and nutrition research has put more consideration in replacing saturated fatty acids and trans fat with unsaturated fatty acids as they play many beneficial roles in human body by reducing inflammation, cholesterol level and stabilize heart beats.12 Therefore, polyunsaturated fatty acids (PUFAs) also called beneficial fats should be supplied through dietary intake at an adequate level as human body is not capable to produce them. The widespread use of plant oils is mainly due to high proportion of PUFAs. Tiny black seeds of chia plant (Salvia hispanica) are rich in protein (16-24%), oil (20-33%), dietary fiber (18-30%), carbohydrates (25-41%), vitamin-B and mineral matter.13 Their nutritional benefits are well-documented and highly acknowledged. Chia oil is extremely salubrious as α-linolenic and linoleic fatty acids encompass 80% of fatty acid proportion.14

Incorporation of oil in yoghurt significantly improves its lipids and protein profile as well as supplies essential fatty acids particularly omega-3 fatty acid.13 Researchers fortified common yoghurt with 1.4% chia oil which in turn, enhanced the survivability of probiotics in yoghurt, also reducing time of fermentation as well as improved the viability of lactic acid bacteria.15 An astonishing effect of this oil results in increased satiety when 7-14 g of chia is consumed in the morning.16 Ingestion of chia seed oil leads to an increase in high density lipoprotein (HDL) while serum triglycerides, low density lipoproteins (LDL), very low density lipoproteins (VLDL) are also reduced dramatically.17 It trigger oxidative stress augmenting hepatic antioxidant capacity and plasma density.18

Keeping in view aforementioned facts and findings, objective of present study were to develop yoghurt spread with whole goat milk fortified with chia oil and to assess qualitative parameters through physicochemical, microbiological and sensory analyses during storage with an aim to monitor the degree of amelioration in contrast to control samples.

MATERIALS AND METHODS

Materials

Whole goat milk was procured from Department of Livestock Management, University of Agriculture Faisalabad, Pakistan. Mixture of starter culture (Lactobacillus delbrueckii and Streptococcus thermophilus) was obtained from Institute of Microbiology, UAF. Herbs e.g. cinnamon, poppy, mint and basil were purchased from Montgomery market of Faisalabad city and applied in the form of powder. Commercially used chia oil with brand name “NUTARIK” and various spices i.e. salt, black pepper and sugar were also bought from local markets.

Methods

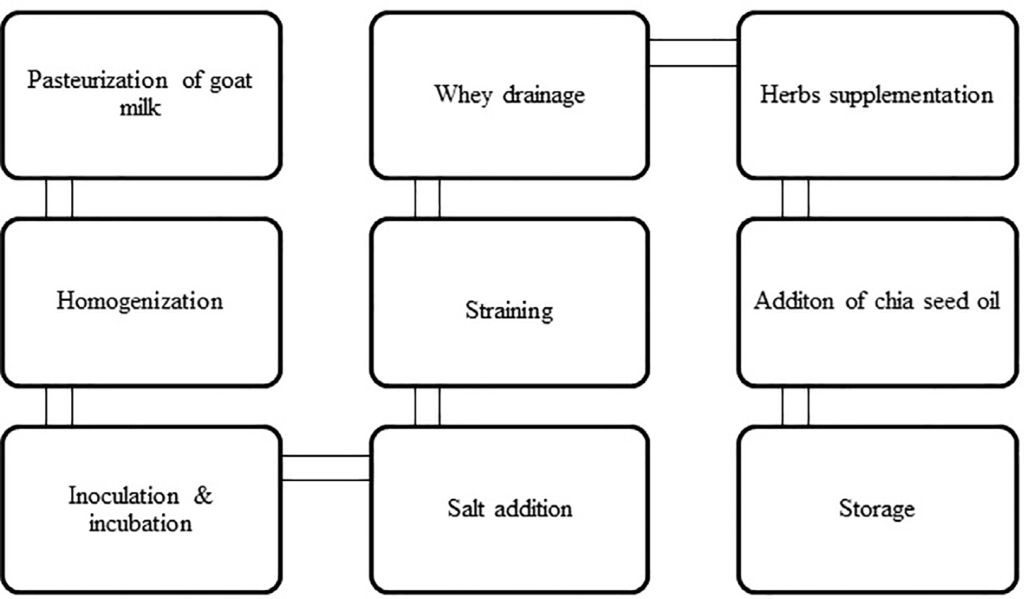

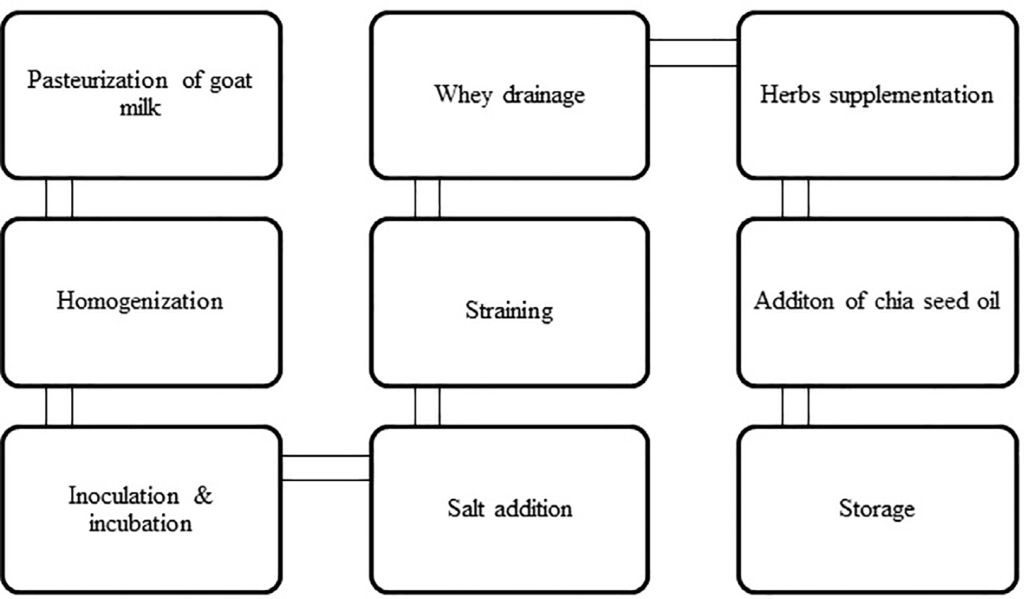

Yoghurt spread formulation: Whole goat milk was pasteurized (72 o C for 30-minutes) and rendered free from microbial contaminants followed by homogenization at 4000 bar pressure using FT9 (single stage) homogenizer. Inoculation with 2% starter culture (Lactobacillus delbrueckii and Streptococcus thermophilus) was accomplished after cooling at 45 o C and then incubated at 42 o C for 4-5-hours for initiation of coagulation till yoghurt attained final potential of hydrogen (pH) 4.6-4.7. Afterwards, yoghurt was conveyed to walk-in cooler set at 4 o C with subsequent addition of 2% NaCl. Straining of yoghurt was done in cheese cloth bags which were then hanged overnight for whey drainage under refrigerated environment. Yoghurt spread obtained was then stored in polyvinylchloride containers and herbs were added.5 Fresh yoghurt spread sample served as control (T0 ) while three other batches containing chia oil at concentrations of 2, 4 and 6% were formulated and entitled T1 , T2 and T3 respectively (Figure 1).

Figure 1. Flow Sheet Diagram for Manufacture of Yoghurt Spread from Goat Milk and Supplementation with Culinary Herbs and Chia Seed Oil

Physicochemical analyses: The samples of yoghurt spread were analyzed for pH, moisture, ash, acidity, total protein, fat and total soluble solids (TSS) during storage span after an interval of 10- days. Every experiment was performed in triplicate for control as well as other formulations and average values were documented.

pH: pH (hydrogen ion concentration) of yoghurt samples was determined by using pH meter.19 Electrode was standardized following the standard operating procedures (SOPs) and inserted in the beaker containing sample. Reading displayed on the digital screen was cautiously documented.

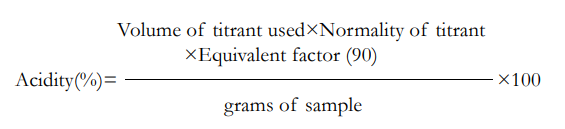

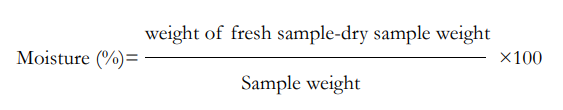

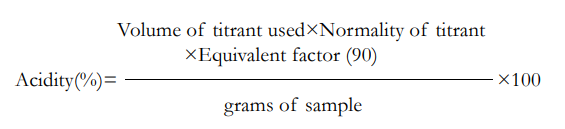

Acidity (%): With the help of Pasteur pipette transferred 20 ml sample, 99.5% ethyl alcohol, sulphuric acid and 2-3 drops of 1% phenolphthalein indicator in Erlenmeyer flask and mixed gently. Titration was carried out with titrant 0.1 N NaOH until color of solution was changed to pink.20 Volume used for titration was multiplied with acidity factor according to following formula,

TSS (oBrix): Total soluble solids were measured by digital bench refractometer. Before using, refractometer was calibrated by deionized water (0o Brix and refractive index=1.3330) and well cleaned. An adequate amount of sample was positioned by means of glass rod on prism surface and viewed in the direction of light.19 The displayed reading was recorded as % Brix as 1% brix is equivalent to 1 g sugar/100 g of solution.

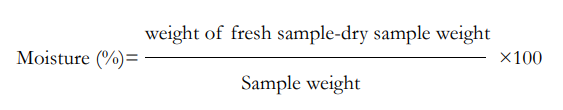

Moisture (%): Oven drying method was used to determine moisture by subtracting dry weight from initial weight at a temperature maintained at 105±5 o C. Samples were kept in desiccator containing absorbents until constant weight was attained.21

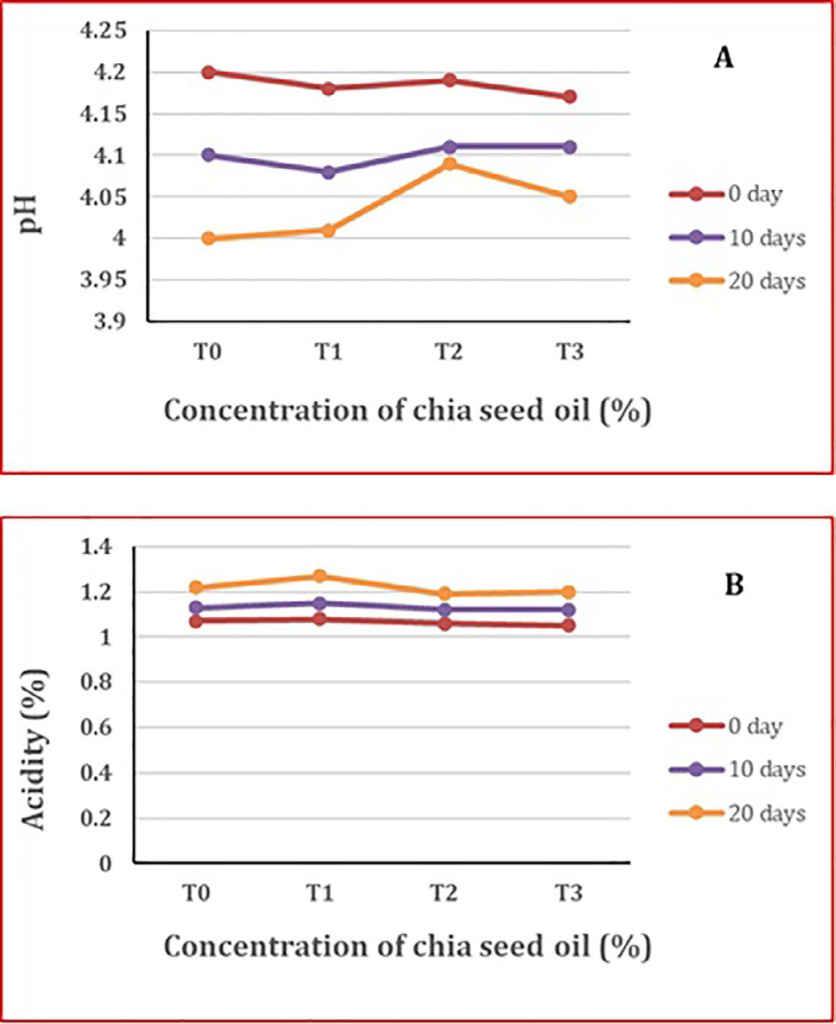

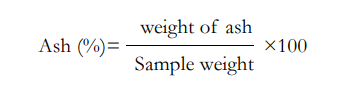

Ash (%): Samples were burnt on red flame until smoke free and remaining residue were transferred to a muffle furnace at a temperature not exceeding 550-600 °C for 8-hours until white ash was obtained.21 Ash percentage was calculated by putting values in given formula.

Fat (%): Sample was mixed thoroughly to minimize incorporation of air maintaining temperature at 20 o C. With the aid of automatic dispenser 10 ml sulfuric acid and appropriate quantity of sample were poured in butyrometer respectively ensuring the gentle flow. One (1) ml isoamyl alcohol was later added to the aforementioned mix. Butyrometer was sealed by a stopper, inverted and placed in water bath for 5-minutes at 65±2 o C dissolving casein particles fully and centrifuged it at 1100 rpm for 5-minutes. Again butyrometer tube was placed in water bath to ensure water level was high enough to heat fat column.22 Fat percentage was observed by adjusting position of stopper and reading lower meniscus.

Total protein (%): Nitrogen content in yoghurt samples was assessed by means of Kjeldahl apparatus.19 The required amount of sample (2 g) was digested in the presence of concentrated H2 SO4 in digestion flask having digestion mixture (K2 SO4 :FeSO4 :CuSO4 i.e. 94:5:1) until the color of solution changed to light greenish.

The digested material was then distilled with 250 ml of water. Ten (10) ml of diluted sample and 10% NaOH was pipetted in distillation assembly and released ammonia (NH3 ) was collected in 4% boric acid solution containing methyl red as an indicator. Ammonia after reaction with boric acid produced ammonium borate which was then titrated with 0.1 N H2 SO4 till it attained the golden brown color. A blank was also run side by side following same steps. Crude protein content was estimated by multiplying nitrogen percent with protein factor (6.38).

Microbial analysis: Seven (7) g nutrient agar was dispersed in 250 ml distilled water and sterilized in an autoclave at 121 °C for 15-20-minutes. Afterwards, it was poured in sterile petri plates and solidified at room temperature. One (1) g sample from control and each formulation was serially diluted transferring 1 ml from each test tube to other through Pasteur pipette. This process was continued until 10-7 dilutions were achieved with less microbial load in last test tube. 0.1 ml aliquot of sample dilution was added to petri plates following spread plate technique and incubated for 48-hours at 37 °C. The bacterial colonies were developed and counted with colony counter in the range of 30-300.23 For every sample TPC was conducted thrice and average values were documented. TPC was calculated as average no. of colonies were multiplied with dilution factor and written as:

Total plate count/gram=Average no. of colonies×dilution factor

Sensory evaluation: The effect of chia oil on sensory traits of yoghurt spread was defined by a panel of trained members (10 men and 10 women) using 1-9 hedonic scale including university students and staff. Panelists were acquainted with sensory assessment techniques and possessed ability to differentiate samples that can be reproducible and repeatable. These parameters were judged from like extremely (1) to dislike extremely (9) for flavor, textureand overall acceptability as described by Hekmat et al.24 For every sample evaluation was conducted thrice and average values were documented.

Statistical Analysis

Data acquired from various parameters was subjected to statistical analysis by using software Statistix-8.1. Two factorial completely randomized design and analysis of variance techniques were applied for the determination of level of significance.25

RESULTS AND DISCUSSION

Physicochemical Analyses

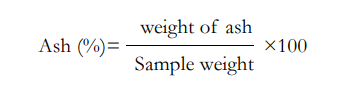

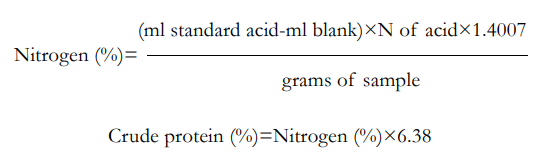

pH: Results denoting mean values for pH of yoghurt spread supplemented with different concentrations of chia seed oil as well as control sample are graphically depicted in Figure 2A. No significant differences were observed with respect to treatments, whereas a fall in pH was depicted significantly (p<0.05) among storage days. Yoghurt spread exhibited maximum pH in fresh condition and with the passage of time reduction trend was perceived. Maximum decrease was observed in T0 and minimum was found in T3 at the terminal stage of storage span of experiment. Results of this finding correlate with outcomes obtained EI-Sayed et al26 in which Moringa oleifera oil was added to ameliorate physicochemical and nutritional values of labneh. As the storage time increased, a decrease in pH was monitored owing to increase in acidity. Increase in microbial population with time causes the available lactose to ferment and convert into lactic acid which contributes majorly to the increase in overall acidity and subsequently pH drops.20

Figure 2. (A) Effect of Chia Seed Oil Supplementation on pH of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

(B) Effect of Chia Seed Oil Supplementation on Acidity (%) of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

Acidity (%): Figure 2B depicts the results for mean values of acidity (%) of yoghurt spread supplemented with different concentrations of chia seed oil and control sample. Acidity (%) of yoghurt spread ranged6 from 1.05 to 1.27. Non-significant decline was noticed among the treatments from T0 to T3 when the concentration of aforesaid oil was varied. On the other hand increment in acidity (%) was found to be significant as the storage days increased and with the passage of time an increasing trend was perceived. Results of our experimentcor related with those obtained by Abilasha et al27 who experienced an increase in percent acidity owing to fermentation of lactose and its conversion into lactic acid. However, the increase or decrease in quantity of sesame seed oil did not affected percent acidity of dairy products to an appreciable extent. Increase in microbial population with time causes the available lactose to ferment and convert into lactic acid which contributes majorly to the increase in overall acidity.6

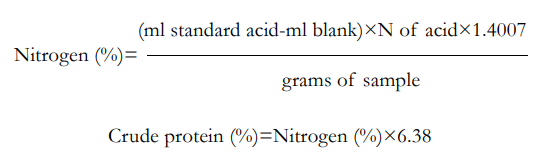

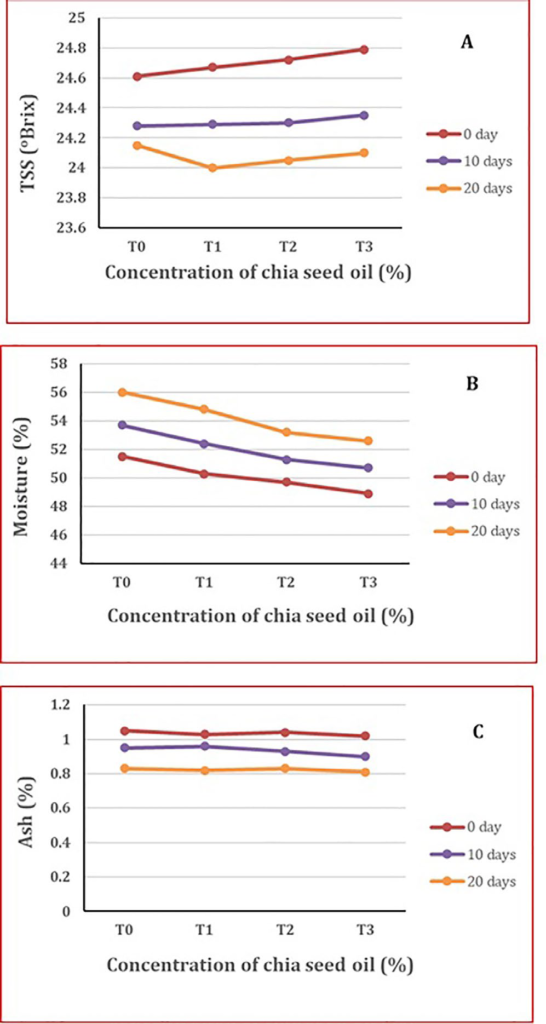

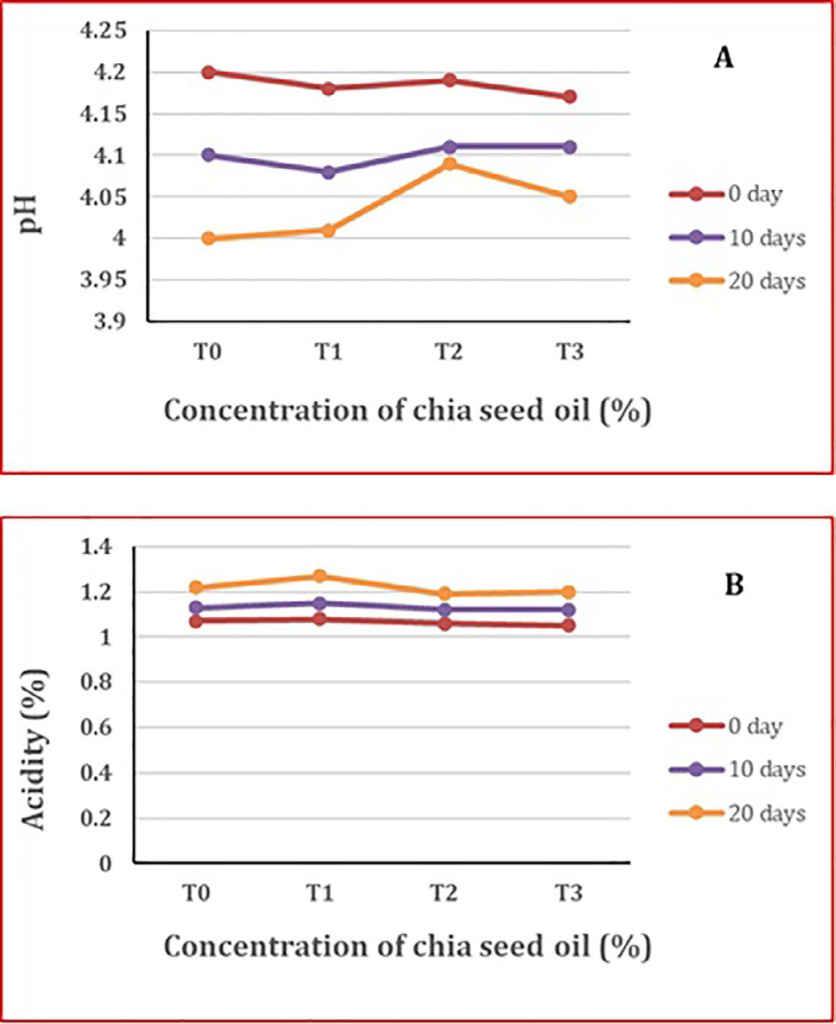

TSS (oBrix): Figure 3A depicts the results for mean values of TSS of yoghurt spread supplemented with different concentrations of chia seed oil and control sample. Yoghurt spread exhibited maximum TSS (o Brix) in fresh condition and with the passage of time a significant reduction trend was perceived. Total solids content was slightly increased with increasing ratio of chia oil compared with control treatment. Findings of our study are similar with Abou-Ayana et al8 and Kowaleski et al.28 Increase in microbial population with time causes the available lactose to ferment which is the prime reason of decline in total solids content.

Figure 3. (A) Effect of Chia Seed Oil Supplementation on TSS of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

(B) Effect of Chia Seed Oil Supplementation on Moisture (%) of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

(C) Effect of Chia Seed Oil Supplementation on Ash (%) of yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil.

Moisture (%): Addition of chia oil had significant effects (p<0.05) on percent moisture content of yoghurt spread as depicted in Figure 3B. Moisture was reduced with increasing oil concentrations. Yoghurt spread exhibited minimum moisture content in fresh condition and with the passage of time an increasing trend was perceived consequently. Maximum increase was observed in T0 and minimum was found in T3 at the terminal stage of storage span of experiment. Miocinovic et al29 conducted qualitative assessment of goat and cow milk yoghurts. They also stated that an increase in the concentration of oil withholds the moisture in aforesaid products. In agreement with these consequences, Kamleh et al30 found an increase in moisture content with increase in storage time while inspecting the quality parameters of Halloumi cheese.

Ash (%): The effect of different concentrations of chia oil on ash content of yoghurt spread during storage has been shown in Figure 3C. There was a non-significant decrease from T0 to T3 however decrease in ash content was found to be significant as the storage days increased. Yoghurt spread exhibited maximum ash content in fresh condition and with the passage of time a decreasing trend was perceived consequently minimum ash content was noticed at 20th days of storage. Kucukcetin et al31 worked on qualitative assessment of goat’s milk yoghurt. They also noticed a decrease in ash content with the passage of time. According to similar observation recorded by Hassabo32 ash content of the concentrated yoghurt decreased with the addition of oil.

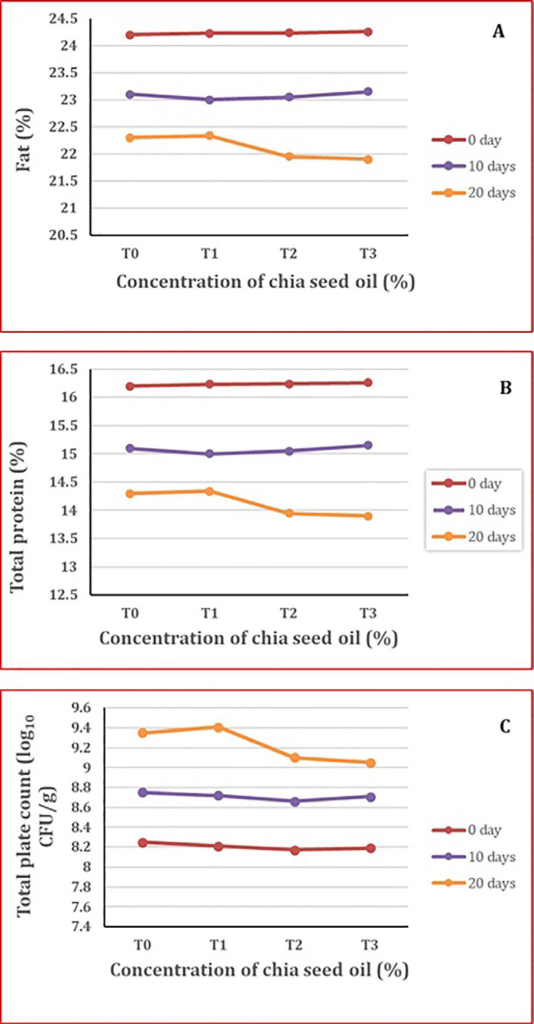

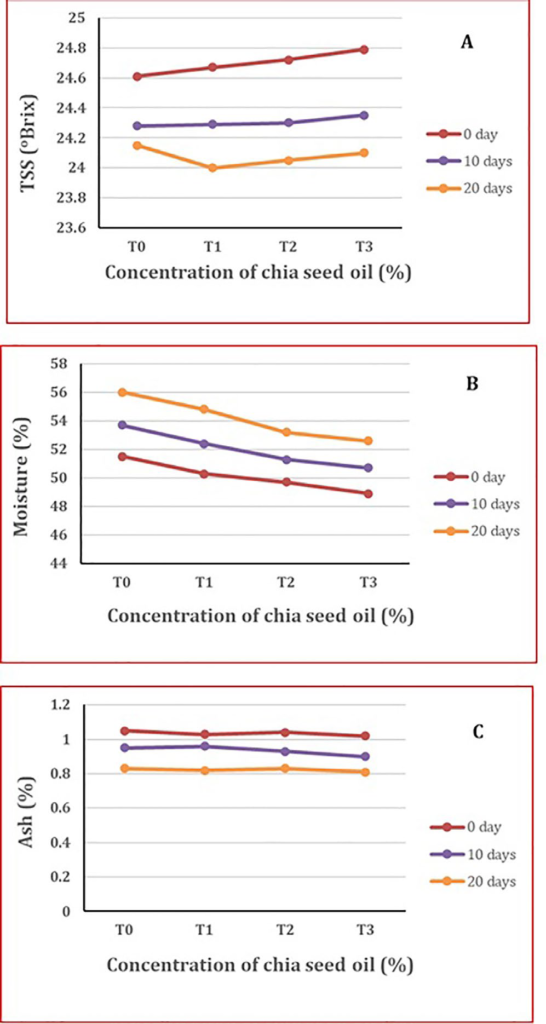

Fat (%): The effect of different concentrations of chia oil on fat content of yoghurt spread during storage was shown in Figure 4A. Fat content of yoghurt spread ranged from 21.90 to 24.26 as presented in Figure 4A. Non-significant increase was noticed among the treatments from T0 to T3 when the concentration of aforesaid oil was varied. On the other hand, decrease in fat content was found to be significant as the storage days increased. The results were in accordance with Gu et al.33 They analyzed quality parameters of yoghurt and noticed a decrease in fat content with the passage of time and accused this decline to lipolysis. Similar observations were recorded by Zaky et al.34

Figure 4. (A) Effect of Chia Seed Oil Supplementation on Fat (%) of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

(B) Effect of Chia Seed Oil Supplementation on Total Protein (%) of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

(C) Effect of Chia Seed Oil Supplementation on Total Plate Count (log10CFU/g) of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil.

Total protein (%): Results denoting mean values for protein content of yoghurt spread supplemented with different concentrations of chia seed oil as well as control sample are graphically depicted in Figure 4B. Fluctuation in chia oil concentrations had non-significant effects (p>0.05) on protein content of yoghurt spread. Protein content was in between the range of 16.26 to 13.90. Minimum total protein content was noticed at 20th days of storage. Highest reduction was observed in T3 and minimum was perceived in T1 . Results of this experiment were correlated with outcomes of Aloglu and Oner who were analyzing the influence of an additive on chemical and sensory characteristics of labneh.35 Similar narration was published by Levy et al36 who recorded an identical reduction trend in protein content of the samples and presented proteolysis as the major factor responsible for this deterioration.

Microbial analysis: Total plate count of yoghurt spread ranged from 8.17 to 9.41 log10 CFU g-1 as presented in Figure 4C. Nonsignificant decrease was noticed among the treatments from T0 to T3 when the concentration of chia seed oil was varied. On the other hand increase in total plate count (log10 CFU g-1) was found to be significant as the storage days increased. Maximum increase was observed in T1 and minimum was found in T3 at the terminal stage of storage span of experiment. The results were in accordance with Eker and Sibel who noticed an increase in plate count (log10 CFU g-1) with the passage of time.37 Similar narration was published by Ahmed and his co-workers in the year 2020.38

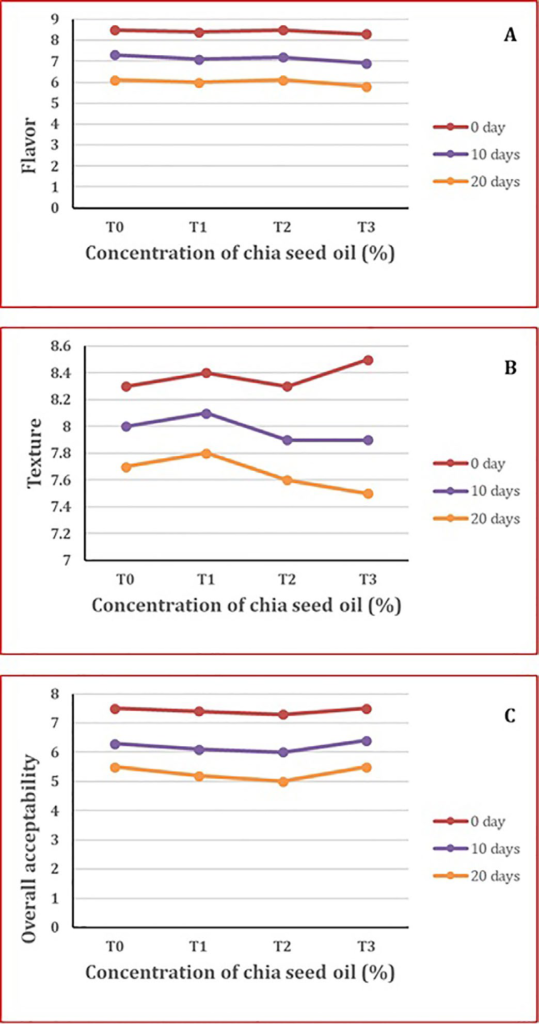

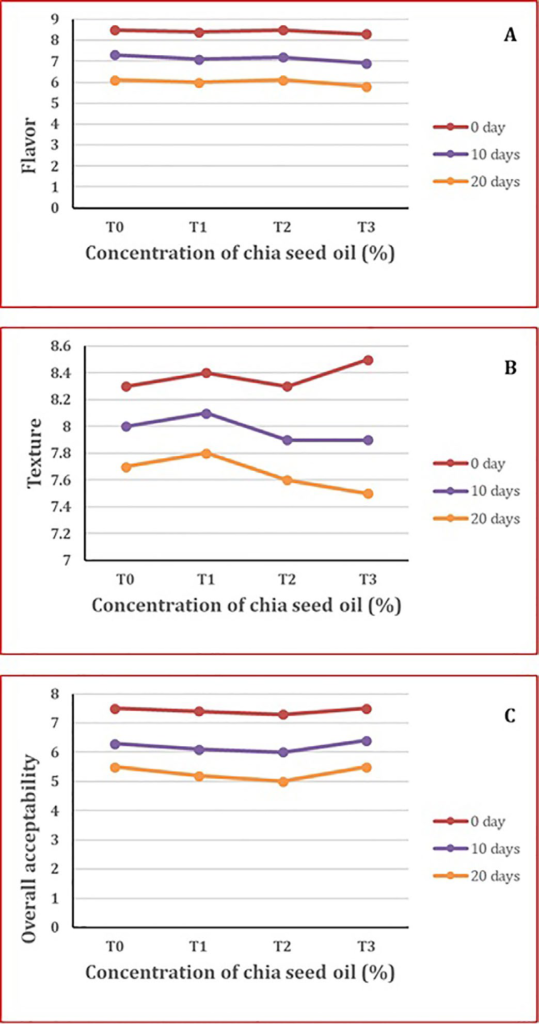

Sensory evaluation: Figure 5 (A, B, C) graphically depict sensory scores of yoghurt spread for control sample and after supplementation with chia seed oil. Yoghurt spread secured maximum sensory scores for texture, flavor and overall acceptability in fresh condition and with the passage of time a reduction trend was perceived consequently minimum sensory scores were noticed at 20th days of storage. Maximum decrease was observed in T3 and minimum was found in T1 at the terminal stage of storage span of experiment. The results obtained by Kibui et al39 supported the results of sensory evaluation of the current study. Generally, addition of chia seed oil at different concentration to yoghurt spread improves the sensory properties and acceptability as well as extends the shelf life and nutritional values as the oil contains appreciable quantity of polyunsaturated fatty acids in particular α-linoleic acid and omega-6.

Figure 5. (A) Effect of Chia Seed Oil Supplementation on Flavor of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

(B) Effect of Chia Seed Oil Supplementation on Texture of Yogurt Spread During Storage. T0: Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

(C) Effect of Chia Seed Oil Supplementation on Overall Acceptability of Yogurt Spread During Storage. T0 : Yogurt Spread without Supplementation; T1 : Yogurt Spread with 2% Chia Oil; T2 : Yogurt Spread with 4% Chia Oil; T3 : Yogurt Spread with 6% Chia Oil

CONCLUSION

Present study revealed that alternating the levels of chia oil as an additive to yoghurt spread ameliorates its physicochemical and sensory profile with non-significant differences in different formulations. However, large extent deterioration is monitored in TSS, ash, protein and acidity with the passage of time. Utilization of cloth bags for processing yoghurt spread provides a premium quality product. An increase in the concentration of chia seed oil withholds moisture and reduces syneresis. Although pH was reduced significantly upon increase in storage span yet it promoted the growth of yeast, bacteria and molds. Incorporation of herbs adds nutritional value and substantially increase the mineral percentage. Generally, addition of chia seed oil at different concentration to yoghurt spread improves the sensory properties and overall acceptability, extends the shelf life and enhances nutritional values. Goat milk is preferable to cow milk owing to essentials nutrients it provides to infants and the substantial therapeutic significance.

CONFLICTS OF INTEREST

The authors declare that they have no conflicts of interest.